17

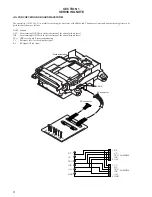

4-5. SELECTING THE TEST MODE

There are 27 types of test modes as shown below. The groups can be switched by pressing the

=

and

=

buttons. After selecting the

group to be used, press the

^

“PROGRAM” button. After setting a certain group, pressing the

=

and

=

buttons switches between

these modes.

Refer to “Group” in the table for details selected.

All items used for servicing can be treated using group S. So be carefully not to enter other groups by mistake.

Display

TEMP CHECK

LDPWR CHECK

EF MO CHECK

EF CD CHECK

FBIAS CHECK

S curve CHECK

VERIFY MODE

DETRK CHECK

TEMP ADJUST

LDPWR ADJUST

EF MO ADJUST

EF CD ADJUST

FBIAS ADJUST

EEP MODE

MANUAL CMD

SVDATA READ

ERR DP MODE

SLED MOVE

Inpossible

ADJ CLEAR

AG Set (MO)

AG Set (CD)

Iop Read

Iop Write

INFORMATION

CPLAY MODE

CREC MODE

Contents

Temperature compensation offset check

Laser power check

Traverse (MO) check

Traverse (CD) check

Focus bias check

S letter check

Non-volatile memory check

Detrack check

Temperature compensation offset adjustment

Laser power adjustment

Traverse (MO) adjustment

Traverse (CD) adjustment

Focus bias adjustment

Non-volatile memory control

Command transmission

Status display

Error history display, clear

Sled check

No function

Initialization of non-volatile memory of adjustment value

Auto gain output level adjustment (MO)

Auto gain output level adjustment (CD)

IOP data display

IOP data write

Microprocessing version display

Continuous play mode

Continuous recording mode

Mark

(

X

)

(

X

)

(

X

)

(X

) (!)

(

X

)

(

X

)

(X

)

(

X

)

Group (

*

)

C

S

C

S

C

S

C

S

C

S

C

C

C

A

S

A

S

A

S

A

S

A

S

D

D

D

S

D

D

A

S

A

S

A

S

C

S

A

S

C

S

C

A

S

D

C

A

S

D

Group (

*

)

C: Check

S: Service

A: Adjust

D: Develop

• For details of each adjustment mode, refer to “5. Electrical Adjustments”.

For details of “ERR DP MODE”, refer to “Self-Diagnosis Function” on page 2.

• If a different mode has been selected by mistake, press the

p

“PROGRAM” button to exit that mode.

• Modes with (

X

) in the Mark column are not used for servicing and therefore are not described in detail. If these modes are set accidentally,

press the

p

“PROGRAM” button to exit the mode immediately. Be especially careful not to set the modes with (!) as they will overwrite

the non-volatile memory and reset it, and as a result, the unit will not operate normally.