66

Wave User Manual

Version 4

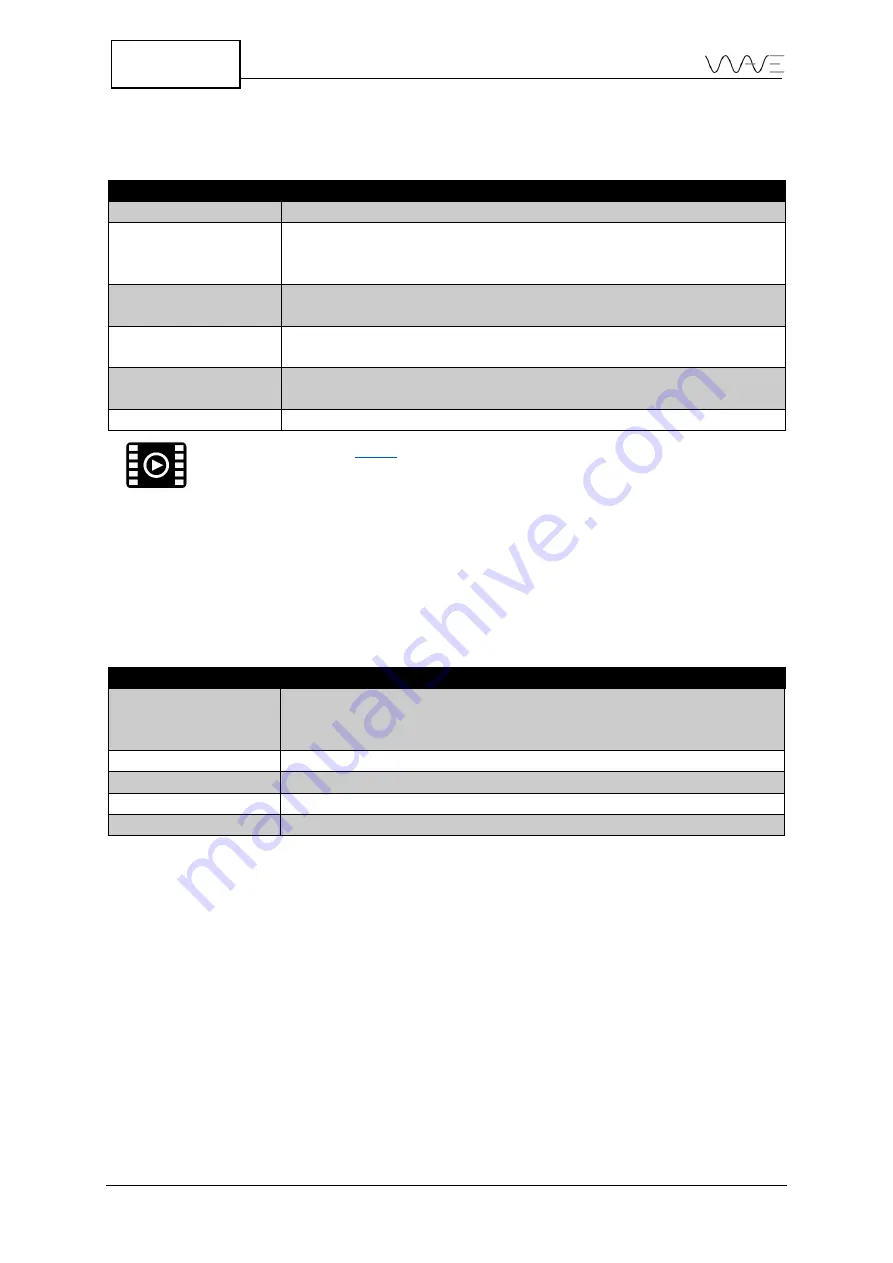

Once a DGS probe is selected, you may set some additional parameters.

Table 23

–

Additional parameters for DGS sizing options

Option

Meaning

Ref. Attenuation

Attenuation finds the attenuation losses at the calibration step.

Material Att.

Material attenuation of the test piece. Once the DGS calibration is

done, it applies the attenuation effect on all DGS curves.

Ref. Type

Reference echo can be a side-drilled hole, flat bottom hole or the

infinite reflector size, also known as the backwall echo.

Ref. Type

Reference echo can be a side-drilled hole, flat bottom hole or the

infinite reflector size, also known as the backwall echo.

Ref. Size

Reference size during the calibration, its type is defined in the

Ref.

Type

tile

Ref. Block Velocity

The velocity of the reference block

for how to create a DGS curve.

12.4.2

DGS Sizing Options

Once a DGS curve is created, there are the following options available on

DGS

sizing

options menu.

Table 24

–

Information regarding the DGS sizing options

Option

Meaning

Transfer Loss

The Transfer Loss is the gain to compensate for the difference of

attenuation between a reference standard and the part to be

inspected.

DGS Trigger

It sets the trigger of the alarm when DGS curve is on (DGS or G1).

Gain Mode

Absolute or relative

ERS

Equivalent Reflector Size

DGS Subcurves

Ref, ERS or dB

12.5

AWS

You can evaluate discontinuities according to AWS D1.1

(American Welding Society)

. This

evaluation is based on signal amplitude comparison. The echo amplitude from a

discontinuity is compared to the echo amplitude of a known reflector. It is defined as an

indication rating according to the code. Sound attenuation in test part is also taken into

account for evaluation.