23

Troubleshooting

Adjustments & Service

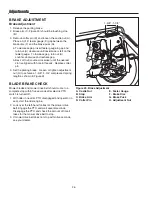

TROUBLESHOOTING

While normal care and regular maintenance will extend

the life of your equipment, prolonged or constant use

may eventually require that service be performed to

allow it to continue operating properly.

The troubleshooting guide below lists the most common

problems, their causes and remedies.

See the information on the following pages for instruc-

tions on how to perform most of these minor adjustments

and service repairs yourself. If you prefer, all of these

procedures can be performed for you by your local

authorized dealer.

WARNING

To avoid serious injury, perform maintenance on the

tractor or mower only when the engine is stopped and

the parking brake engaged.

Always remove the ignition key, disconnect the spark

plug wire and fasten it away from the plug before

beginning the maintenance, to prevent accidental

starting of the engine.

TROUBLESHOOTING THE RIDER

PROBLEM

CAUSE

REMEDY

Engine will not turnover or start.

1. Ground speed control lever

1. Shift into neutral.

not in neutral-start position.

2. PTO (electric clutch) switch

2. Place in OFF position.

in ON position.

3. Out of fuel.

3. If engine is hot, allow it to cool, then refill the

fuel tank.

4. Engine flooded.

4. Open the CHOKE.

5. Circuit breaker tripped.

5. Wait one minute for automatic reset. Replace

if defective (see your dealer).

6. Battery terminals require cleaning.

6. See Normal Care section.

7. Battery discharged or dead.

7. Recharge or replace.

8. Wiring loose or broken.

8. Visually check wiring & replace broken or

frayed wires. Tighten loose connections.

9. Solenoid or starter motor faulty.

9. Repair or replace. (see your dealer.)

10. Safety interlock switch faulty.

10. Replace if needed (see your dealer.)

11. Spark plug(s) faulty, fouled or

11. Clean and gap or replace.

incorrectly gapped.

See engine manual.

12. Water in fuel.

12. Drain fuel & refill with fresh fuel.

13. Old stale gas.

13. Drain fuel & replace with fresh fuel.

14. Brake pedal not depressed.

14. Depress pedal.

Engine starts hard or runs poorly.

1. Fuel mixture too rich.

1. Open the CHOKE.

If problem persists, clean the air filter.

(See engine manual.)

2. Carburetor adjusted incorrectly.

2. See engine manual.

3. Spark plug(s) faulty, fouled, or

3. Clean & gap or replace. See engine manual.

incorrectly gapped.

Engine knocks.

1. Low oil level.

1. Check/add oil as required.

2. Using wrong grade oil.

2. See engine manual.

Excessive oil consumption.

1. Engine running too hot.

1. Clean engine fins, blower screen and air

cleaner.

2. Using wrong weight oil.

2. See engine manual.

3. Too much oil in crankcase.

3. Drain excess oil.

Engine exhaust is black.

1. Dirty air filter.

1. Clean air filter. See engine manual.

2. Choke not fully open.

2. Open CHOKE.

If problem persists, check air filter and

carburetor adjustments. See engine manual.