15.

Assembly and adjustments

Miter gauge adjustment (Fig. 18)

Place the miter gauge in the groove on the table. The

miter gauge can be adjusted 0° to 60° right and left to

maintain an accurate angle on your workpiece. To

adjust the angle on the miter gauge:

1. Turn the miter gauge knob

(1)

counterclockwise to

loosen.

2. Rotate the base of the gauge to align the pointer

(2)

with the desired angle.

3. Tighten the miter gauge knob

(1)

.

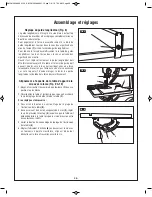

Wheel brush adjustment (Fig. 19)

The wheel brush is located against the lower blade

wheel and helps keep the blade clean of sawdust and

wood chips.

If an adjustment is needed:

1. Loosen the screw

(3)

that secures the wheel

brush

(4)

.

2. Position the wheel brush against the wheel.

3. Tighten the screw.

Drive belt adjustment (Fig. 19 & 20)

Check the deflection of the drive belt

(5)

in the center

between the two pulleys on the opposite side from the

belt tension wheel. The belt should deflect 1/4" (6 mm)

deflection when pressing on the drive belt in the center

between the two pulleys.

1. Loosen, but do not remove, the two bolts

(6)

that hold

the motor assembly to the housing.

2.

To reduce the tension on the belt:

pull the motor

assembly

(7)

up (counterclockwise).

To increase tension on the belt:

push the motor

assembly down (clockwise).

3. Tighten the two bolts that hold the motor to the

housing.

FIG. 18

FIG. 20

2

1

FIG. 19

4

5

6

6

7

3

SM 2610028633 01-13_SM 2610028633 01-13.qxp 1/9/13 7:24 AM Page 15