13.

Assembly and adjustments

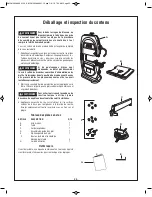

Adjust the upper blade guide (Fig. 13–14)

1. Make sure the upper blade guide assembly

(1)

is at

right-angles to the blade

(2)

.

If not:

loosen the screw

(3)

and rotate the assembly

until it is perpendicular to the blade, then re-tighten

the screw

(3)

.

2. Loosen the support bearing screw

(4)

and move the

support bearing

(5)

forward or backward until the

bearing is 1/32" (0.8 mm) behind the blade. Tighten

the screw

(4)

.

3. Loosen the left and right blade guide screws

(6)

and

move the guides

(7)

as close to the blade as possible

without pinching it. Using a feeler gauge (not

provided), make sure the space between each guide

and the blade measures 0.02" (0.5 mm). Tighten the

screws

(6)

.

Adjust the lower blade guides (Fig. 15)

It is possible to adjust lower blade guide with table

attached, however user may find it easier to do so with

table removed.

1. Loosen the lower support bearing screw

(8)

. Move

the support bearing

(9)

forward or backward until the

bearing is 1/32" (0.8 mm) behind the blade

(2)

.

2. Loosen the lower blade guide screws

(10)

and move

the left and right blade guides

(11)

as close to the

blades as possible without pinching it. Using a feeler

gauge (not provided), make sure the space between

each guide and the blade measures 0.02" (0.5 mm).

Tighten both screws

(10)

.

3.Reattach table (if removed), taking care not to bump

the table against the blade.

Set blade guide assembly height (Fig. 16)

The blade guide assembly should be set approximately

1/8" (3.2 mm) above the workpiece.

1. Loosen the blade guide lock knob

(1)

.

2. Rotate the blade guide adjustment knob

(2)

to lower

the blade guide assembly

(3)

.

3. Tighten the blade guide lock knob

(1)

.

FIG. 14

6

6

7

7

FIG. 15

8

2

FIG. 16

9

1

10

11

11

2

3

FIG. 13

3

2

1

5

2

4

SM 2610028633 01-13_SM 2610028633 01-13.qxp 1/9/13 7:24 AM Page 13