53

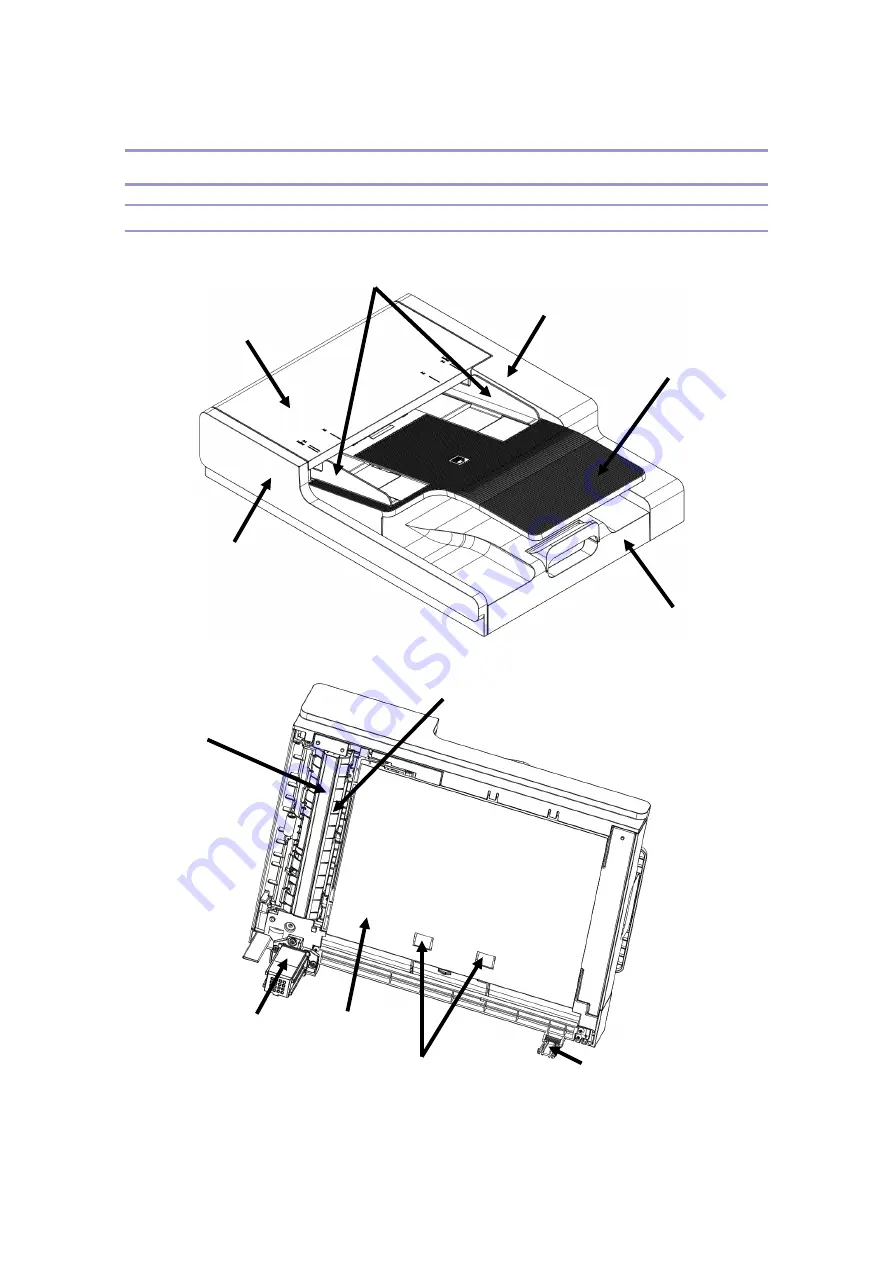

ADF (Auto Document Feeder)

Overview

Auto Document Feeder(called ADF afterwards) is a device for scanning the original by

ADF front cover

ADF Front cover

ADF side fence

ADF rear cover

ADF doc. tray

ADF main frame

ADF upper guide

ADF pressure plate

ADF left hinge

ADF back

plate

ADF A3 roller

ADF right hinge

Summary of Contents for M611

Page 1: ...FIELD SERVICE MANUAL M611 M616 M612 M617 CS 2014 6 13 CE Confid ential...

Page 20: ...14 MFP Overview MFP Components...

Page 22: ...16 Paper Path 1 Output bin 2 Manual Tray 3 Base Unit Tray 4 Optional Tray Unit 5 Duplex Unit...

Page 43: ...37...

Page 88: ...82 3 24V Output Section...

Page 89: ...83 4 5V Output Section...

Page 90: ...84 5 AC Drive Section 6 Switching Section...

Page 91: ...85 Circuit HVPS Input Section 1 PWM Input Section...

Page 92: ...86 2 RCC Control Drive Section...

Page 93: ...87 3 High Power Output Section 4 TX SENSING...

Page 94: ...88...

Page 128: ...122 Removing Optional Acufeed Unit 1 Remove 2 harnesses and then 5 screws A...

Page 137: ...131 4 Separate the Exit frame with releasing the left and right side bolts...

Page 138: ...132 5 Release the harness bolts which are jointed to the fusing frame...

Page 157: ...151...

Page 214: ......