34

EN

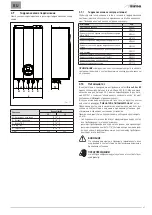

Type

No.

Fault

Solution

ALL

80

Fault on the valve

control logic line/valve

cable damaged

- Check gas valve and board

ALL

81

Block due combustion

during start-up

- Check for blockage in

chimney

- Check air diaphragm (for

BF models)

- Check gas calibration

- Bleed the air from the gas

circuit

ALL

82

Block due to nu-

merous combustion

control failures

- Check electrode

- Check outlets

- Check air diaphragm (for

BF models)

- Check gas calibration

ALL

83

Irregular combustion

(temporary error)

- Check for blockage in

chimney

- Check air diaphragm (for

BF models)

- Check gas calibration

ALL

84

Flow rate reduced for

(presumed) low pres-

sure on mains gas

- Check gas flow rate

ALL

88

Internal error (board

component protection)

- Check the board is

working

- Replace board

ALL

89

Unstable combustion

feedback signal error

- Check electrode

- Check outlets

- Check air diaphragm (for

BF models)

- Check gas calibration

ALL

90

Combustion set can-

not be reached error

- Check electrode

- Check outlets

- Check air diaphragm (for

BF models)

- Check gas calibration

ALL

91

Gas valve out of range - Recalibrate the gas valve

ALL

92

System has reached

maximum air cor-

rection error (at the

minimum flow rate)

- Check electrode

- Check outlets

- Check air diaphragm (for

BF models)

- Check gas calibration

Type

No.

Fault

Solution

ALL

93

Combustion set can-

not be reached error

- Check electrode

- Check outlets

- Check air diaphragm (for

BF models)

- Check gas calibration

ALL

95

Flame signal micro

interruptions error

- Check electrode

- Check board

- Check electric power

supply

- Check gas calibration

ALL

96

Block due to clogging

in smoke outlet

- Check for blockage in

chimney

- Check the smoke outlet

and electrode position (not

touching the burner)

ALL

98

SW error, board

start-up

- Contact the Technical

Assistance Centre

ALL

99

General board error

- Contact the Technical

Assistance Centre

-

-

Frequent relief valve

intervention

- Check circuit pressure

- Check expansion vessel

-

-

Limited production of

domestic hot water

- Check the diverter valve

- Check that plate heat

exchanger is clean

- Check domestic hot water

circuit valve

4.6.1

Maintenance request

When it is time to perform maintenance on the boiler, the

c

symbol shows on the display.

Contact the technical assistance service to organise the neces-

sary work.