TXP-CLC

Course

2

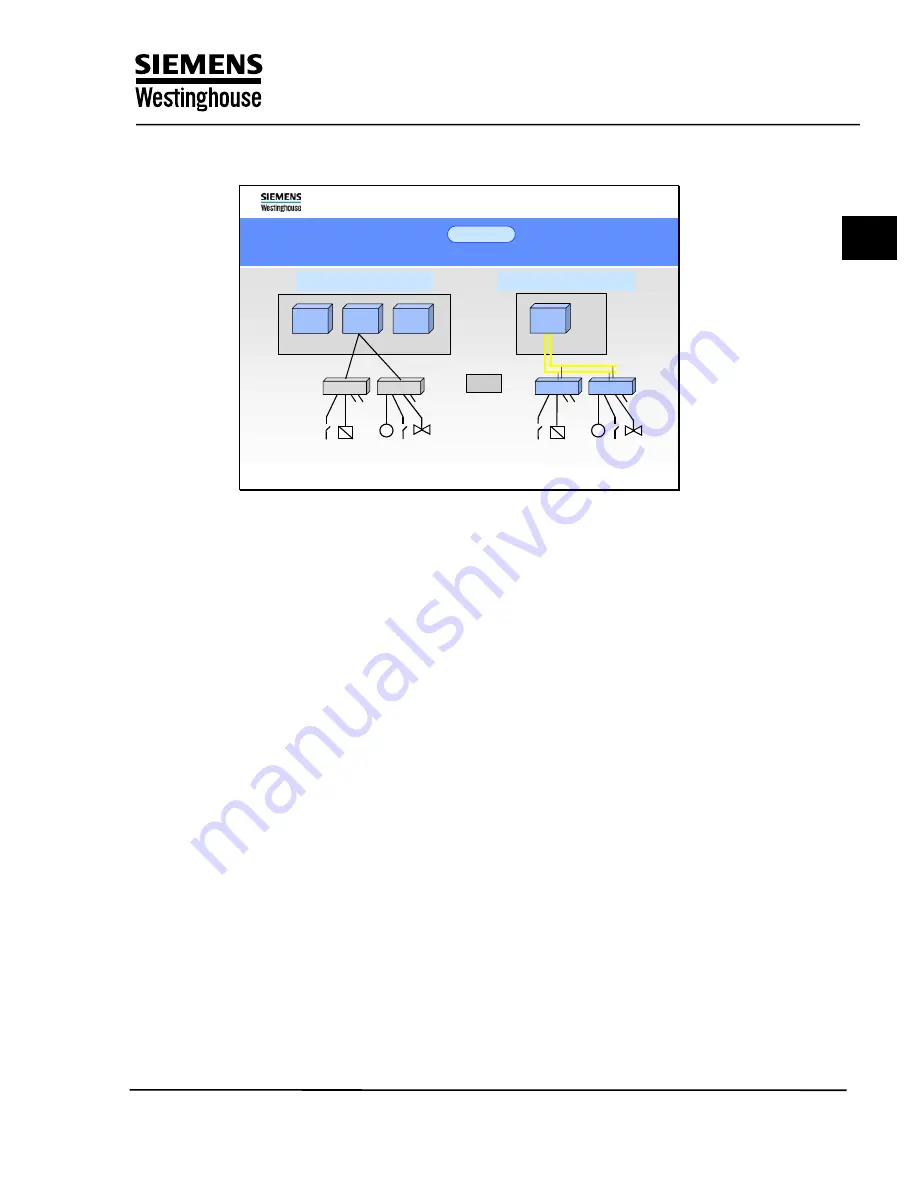

Alternative solutions with AS 620 B (2)

Function modules (FUM) and/or Signal modules (SIM)

M

M

Field

Field

Field

Profibus

Profibus

AP

AP

FUM

FUM

FUM

FUM

FUM - Configuration

FUM - Configuration

I&C room

I&C room

I&C room

I&C room

Centralized

Centralized

Distributed

Distributed

AP

AP

JB

JB

JB

JB

SIM B

SIM B

SIM B

SIM B

SIM - Configuration

SIM - Configuration

SIM modules

SIM modules are used for the input and output of analog and binary signals.

Their task is to digitize process signals and to output digital settings as binary or

analog signals. More complex tasks such as signal processing, monitoring, and

time-tagging are performed in the AP. A signal module in conjunction with the

associated function block performs the same function as the corresponding FUM.

SIMs are modules from the SIMATIC S5/S7, ET200 B/ET200 M range, which

allows the input and output modules to be installed locally in the process

environment instead of centrally in the automation system. For this purpose, the

modules are combined into stations and located in the immediate vicinity of the

field devices, installed in distribution boxes or wall-mounted housings for

example.

The advantage of a distributed configuration lies in the minimal space

requirements in the computer room, because only the cabinets for the AP are

installed there. Savings can also be made in wiring costs because only the loop-

in cable from the I/O to the nearest station is required.

Distributed configurations also permit the automation processors and the input

and output modules in the process environment to be located a considerable

distance apart. The SIM modules are linked with the automation processor via

PROFIBUS. PROFIBUS can be operated at a maximum data transmission rate

of 1.5 Mbit/s and is also available in a fiber-optic version for use under adverse

interference conditions or where lightning protection is required.

The flexibility of the automation system allows the FUM structure to be combined

with the distributed SIM structure, which supports the implementation of tailor-

made solutions.

Training Center

Copying of this document, and giving it to others and use or communication of the contents, are forbidden without express authority. Offenders are liable to the payment of

damages. All rights are reserved in the event of the grant of a patent or the registration of a utility model or design.

3

Summary of Contents for TXP-CLC

Page 5: ...TXP CLC Course 1 TXP Overview Training Center ...

Page 11: ...TXP CLC Course 2 Automation System AS620 Training Center ...

Page 19: ...TXP CLC Course 3 Industrial Ethernet Training Center ...

Page 29: ...TXP CLC Course 4 Engineering system ES680 Training Center ...

Page 45: ...TXP CLC Course 5 KKS Overview Training Center ...

Page 81: ...TXP CLC Course 6 Training Project Exercise 1 2 Training Center ...

Page 101: ...TXP CLC Course 7 BT Function Block Exercise 3 Training Center ...

Page 121: ...TXP CLC Course 8 AT Function Block Exercise 4 Training Center ...

Page 137: ...TXP CLC Course 9 CBO Function Block Exercise 5 Training Center ...

Page 145: ...TXP CLC Course 10 CAO Function Block Exercise 6 Training Center ...

Page 155: ...TXP CLC Course 11 DCM Function Block Exercise 7 Training Center ...

Page 187: ...TXP CLC Course 12 Generation Transfer Exercise 8 Training Center ...