4 Technical Data

412

7UM62 Manual

C53000-G1176-C149-3

4.4

Thermal Overload Protection (ANSI 49)

Setting Ranges/

Resolutions

K-Factor per IEC 60255-8

0.10 to 4.00

(Increments 0.01)

Time Constant

τ

30 s to 32000 s

(Increments 1 s)

Extension K-Factor

k

t

- Factor

1.0 to 10.0 relative to the time constant for

when Machine Stopped

the machine running (Increments 0.1)

Thermal Alarm

Θ

Alarm

/

Θ

Trip

70 % to 100 % of the trip temperature rise

(

Θ

ALARM)

(Increments 1 %)

Current Overload

I

Alarm

0.50 A to 20.00 A

1

) (Increments 0.05 A)

1

)

Alarm (I ALARM)

Rated Temperature Rise

40 °C to 200 °C

(Increments 1 °C)

at Rated Sec. Current

104 °F to 392 °F

(Increments 1 °F)

Cooling Medium Temperature

40 °C to 300 °C

(Increments 1 °C)

for Scaling

104 °F to 572 °F

(Increments 1 °F)

Current Limiting

I

Max therm.

2.50 A to 40.00 A

1

) (Increments 0.05 A)

1

)

Emergency Time

10 s to 15000 s

(Increments 1 s)

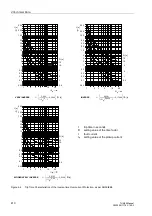

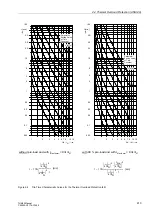

Trip Characteristic

Curve

See also Figure 4-4

Dropout Relations

Θ

/

Θ

trip

Drops out with

Θ

Alarm

Θ

/

Θ

Alarm

Approx. 0.99

I

/

I

Alarm

Approx. 0.95

Tolerances

Referring to k ·

I

N

2 % or 50 mA

1

); 2 % class per

IEC 60255–8

Thermal Trip and Alarm Times

3 % or 1 s for I/(k ·I

N

) > 1.25;

3 % class per IEC 60255–8

Influencing

Variables Referring

to [k ·

I

N

]

Power Supply DC Voltage (U

DC

) in Range

0.8

≤

U

PS

/ U

PS nominal

≤

1.15

1 %

Temperature in Range

23 °F

≤ ϑ

amb

≤

131 °F

0.3 % / 10 °F

–5 °C

≤ ϑ

amb

≤

55 °C

0.5 % / 10 K

Frequency in Range

0.95

≤

f/f

N

≤

1.05

< 1 %

1

) For I

N

= 1 A, divide all limits and increments by 5.

t

τ

I

k

I

N

⋅

-------------

è

ø

æ

ö

2

I

pre

k

I

N

⋅

-------------

è

ø

æ

ö

2

–

I

k

I

N

⋅

-------------

è

ø

æ

ö

2

1

–

-------------------------------------------------

ln

⋅

=

Trip Characteristic Curve

t

Trip time

τ

Temperature rise time constant

I

Load current

I

pre

Pre-load current

k

Setting factor per VDE 0435

Part 3011 and IEC 60255–8

I

N

Nominal current of the device

I

Max therm.

Current threshold up to which

the above formula is valid

Where:

for (

I

/ k

·

I

N

)

≤

I

Max therm.