Auxiliary Function Outputs to PLC (H2)

9.3 Transfer of values and signals to the PLC interface

Turning, Milling, Nibbling

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

159

Programming

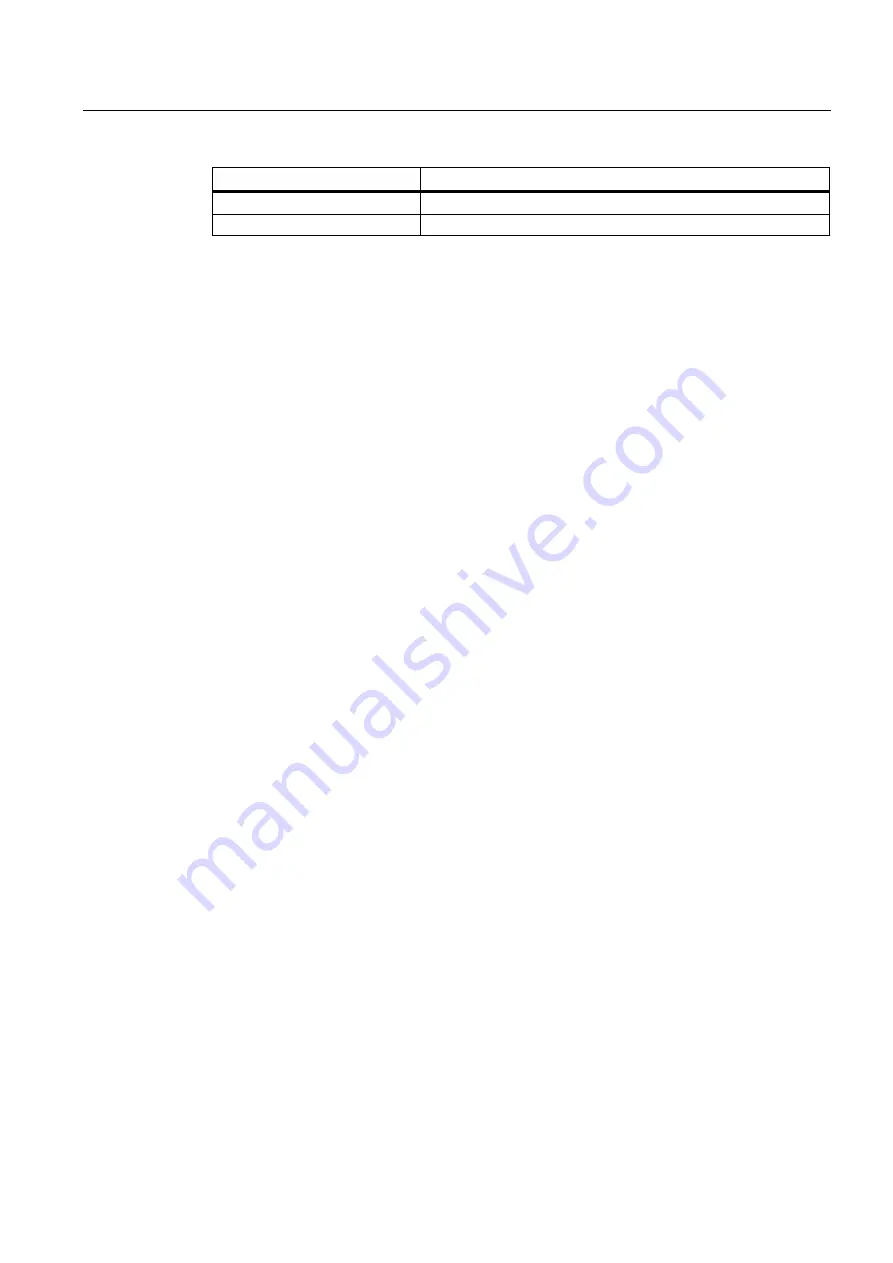

Output of H function to the PLC

H17=3.5

H17=3.5

H5.3=21

Error, alarm 14770

Block change

A new auxiliary function output from the NCK to the PLC is only possible after the PLC has

acknowledged all transferred auxiliary functions. Auxiliary functions are present in the user

interface for at least one PLC cycle. A block is considered as completed when the

programmed movement has been completed and the auxiliary function has been

acknowledged. To do so, the NCK stops the part program processing if necessary to ensure

that no auxiliary functions are lost from the PLC user program's point of view.

9.3

Transfer of values and signals to the PLC interface

Time of transfer

In the case of auxiliary functions which are output at the end of a block (e.g. M2), the output

is only made after all axis movements and the SPOS movement of the spindle have been

completed.

If several auxiliary functions with different output types (prior, during, at end of motion) are

programmed in one motion block, then they are output individually according to their output

type.

In a block without axis movements or SPOS movement of the spindle, the auxiliary functions

are all output immediately in a block.

Continuous-path mode

A path movement can only remain continuous if auxiliary function output takes place during

the movement and is acknowledged by the PLC before the path end is reached, see Chapter

"Continuous Path Mode (B1)".

Interface signals

Transfer of the signals from NCK to the PLC:

Reference:

/LIS/ SINUMERIK 802D sl lists