Velocities, Setpoint/Actual Value Systems, Closed-Loop Control (G2)

7.3 Setpoint/actual-value system

Turning, Milling, Nibbling

Function Manual, 11/2012, 6FC5397-1CP10-5BA0

123

7.3

Setpoint/actual-value system

7.3.1

General

Block diagram

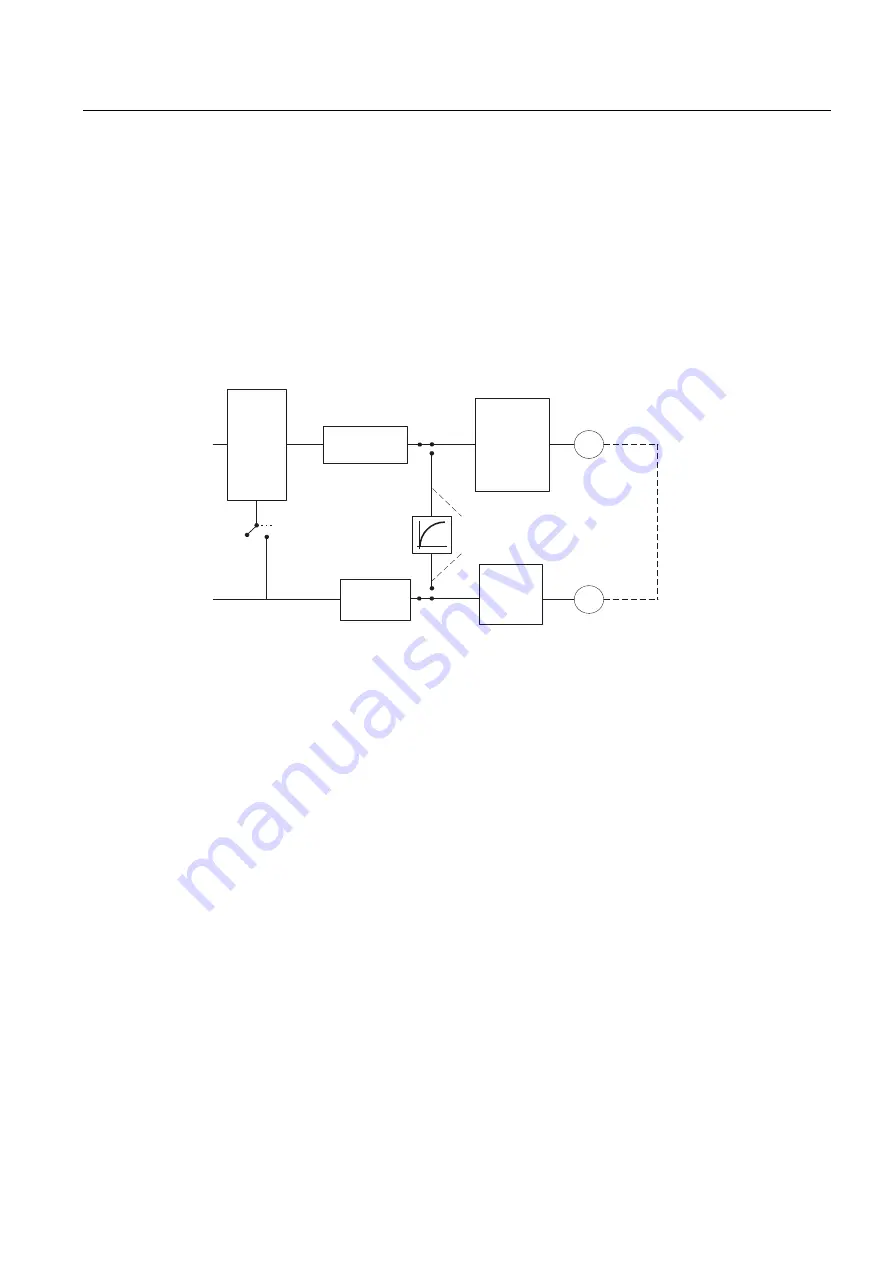

A control loop with the following structure can be configured for every closed-loop controlled

axis/spindle:

0'

(1&B7<3( 6,08/$7,21

0'

&75/287B7<3( 6,08/$7,21

$FWXDO

YDOXH

URXWLQJ

(QFRGHU

0RWRU

,63RVLWLRQPHDVXULQJ

V\VWHP

*

$FWXDOYDOXH

SURFHVVLQJ

0

6SHHG

VHWSRLQW

URXWLQJ

6SHHGVHWSRLQW

RXWSXW

&ORVHGOR

RSFRQWURO

Figure 7-1

Block diagram of a control loop

Setpoint output

A setpoint can be output for each axis/spindle. The setpoint output at the setting device is

done digitally or, in the case of analog spindles 10 V unidirectionally or bidirectionally.

Simulation axes

The speed control loop of an axis can be simulated for test purposes. The axis "traverses"

with a following error, similar to a real axis.

A simulation axis is defined by setting MD30130 CTRLOUT_TYPE[n] (setpoint output type)

and MD30240 ENC_TYPE[n] (actual-value acquisition type) to "0".

As soon as the standard machine data has been loaded, the axes become simulation axes.

The setpoint and actual value can be set to the reference point value with reference point

approach.

MD30350 SIMU_AX_VDI_OUTPUT (output of axis signals for simulation axes) can be set to

define whether axis-specific interface signals are output to the PLC during the simulation

process.