Overview

Special settings for a pulling load

For a pulling load, e.g. a hoisting gear, a permanent force is exerted on the motor, even when

the motor is stationary.

For a pulling load, we recommend that you use vector control with an encoder.

Function description

If you use sensorless vector control with a pulling load, then the following settings are required:

• Set the following parameters:

• When opening the motor holding brake, enter a speed setpoint > 0.

For speed setpoint = 0, and with the motor holding brake open, the load drops because the

induction motor rotates with the slip frequency as a result of the pulling load.

• Set the ramp-up and ramp-down times ≤ 10 s in the ramp-function generator.

• If, in quick commissioning, you have selected application class Dynamic Drive Control then

set p0502 = 1 (technological application: dynamic starting or reversing).

Parameter

Parameter

Description

Factory setting

p1610[D]

Torque setpoint static (without encoder)

50%

p1750[D]

Motor model configuration

0000 0000 0000

1100 bin

8.19.2.4

Friction characteristic

Overview

In many applications, e.g. applications with geared motors or belt conveyors, the frictional

torque of the load is not negligible.

The converter provides the possibility of precontrolling the torque setpoint, bypassing the speed

controller. The precontrol reduces overshooting of the speed after speed changes.

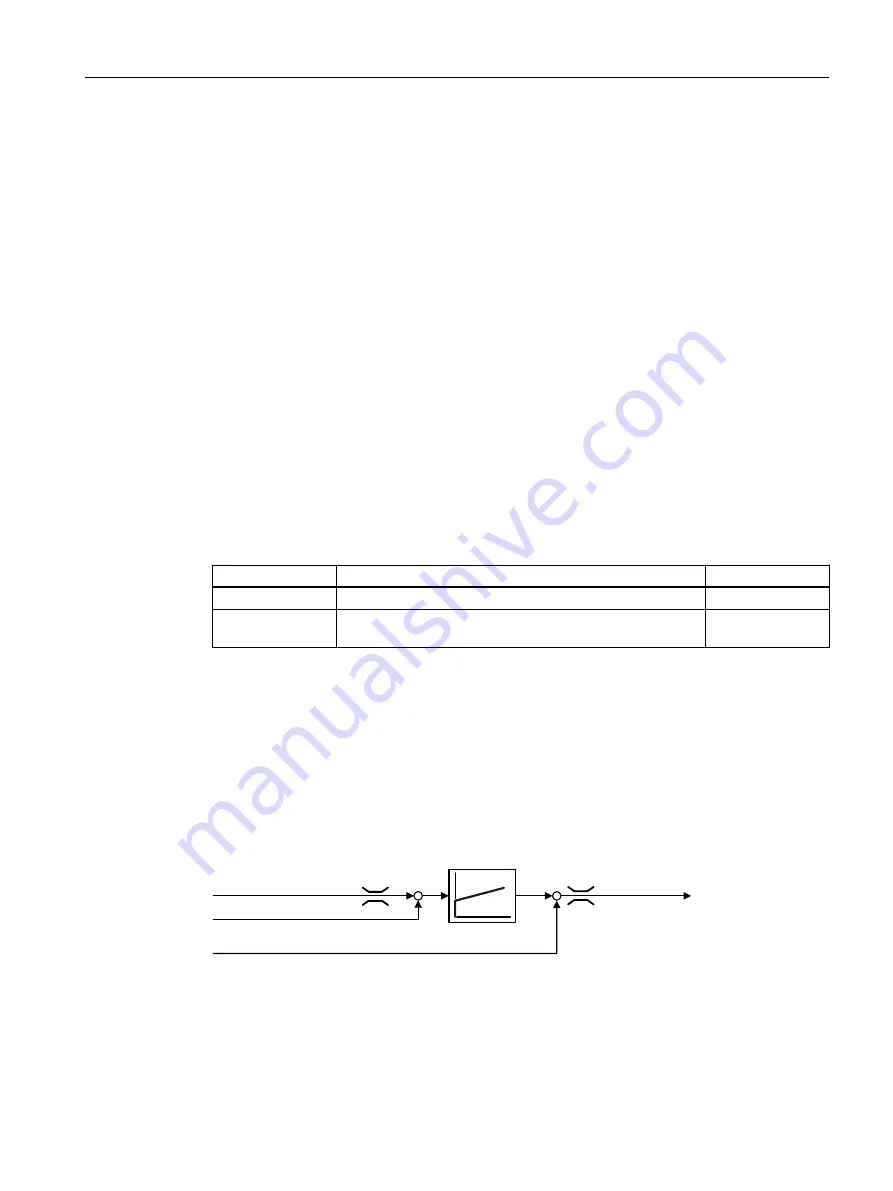

6SHHGVHWSRLQW

)ULFWLRQDOWRUTXH

7RUTXH

VHWSRLQW

6SHHGFRQWUROOHU

6SHHGDFWXDOYDOXH

.

3

7

1

Figure 8-56

Precontrol of the speed controller with frictional torque

The converter calculates the current frictional torque from a friction characteristic with 10

intermediate points.

Advanced commissioning

8.19 Motor control

Distributed converter for SIMOGEAR geared motors

Operating Instructions, 10/2020, FW V4.7 SP13, A5E31298649B AL

301