Mechanical mounting

4.7 Mounting of rotating unions on 1PH8 hollow-shaft motors

1PH808/1PH810 main motors

Operating Instructions, 04/2017, 610.48004.40f

67

4.7

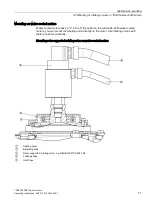

Mounting of rotating unions on 1PH8 hollow-shaft motors

General information

1PH8 main motors with a hollow shaft (13th position in the Article No.: " 3 ") are designed

as main spindle motors for machine tools and machining centers with internal tool cooling.

A rotating union is required for the provision of the coolant in the rotating motor shaft.

A rotor-supported or, for a motor ordered with option Y64, a bearingless, frame-supported

rotating union can be mounted on the NDE shaft extension. In addition to coolant, suitable

rotating unions can also transfer oil mist (minimum quantity lubrication), cutting oils or even

compressed air at standstill.

Rotor-supported rotating unions consist of the following components:

●

Rotor with bearing

●

Stator

●

Enclosure with cable connections

●

Floating-ring shaft seal

Rotor-supported rotating unions are easy to fit and change. They are screwed into the motor

shaft via the thread on the rotor. The advantage of these rotating unions is the leading off of

the leakage via the housing and the integrated leakage connection.

Bearingless, frame-supported rotating unions are made up of two separate parts, the rotating

part with a mechanical seal and the static part with a mechanical seal and supply

connection. By eliminating the bearings, higher speeds can be achieved and the rotating

union is less sensitive to vibrations and lateral loads. However, an adapter such as is

described in Ch. "Suggestion for an adapter for bearingless, frame-supported rotating

unions" for installing the rotating union is required.

Installation must be performed very carefully because the sealing surfaces of the mechanical

seal are not protected.

The rotating part is bolted into the NDE end of the motor shaft. The static part is mounted on

the encoder cover of the motor via an adapter. The adapter must include a facility for

draining leakage. The adapter must be designed in such a way that the motor is not flooded

by the leakage and the degree of protection of the motor is complied with. It may be

necessary to use sealing air.

For use of a bearingless rotating union, the motor must be ordered with option Y64 and the

interface on the encoder cover must be located concentrically with respect to the shaft. The

mounting conditions stated by the manufacturer of the rotating union must be met.

Depending on the type of rotating unions, the sealing rings may be permanently or

temporarily in contact.

Example of a closed seal: DEUBLIN series 1116 and 1108

Example of an opening seal: DEUBLIN series 902 and 1109

Summary of Contents for SIMOTICS M-1PH8

Page 1: ......

Page 2: ......

Page 8: ...Introduction 1PH808 1PH810 main motors 8 Operating Instructions 04 2017 610 48004 40f ...

Page 12: ...Table of contents 1PH808 1PH810 main motors 12 Operating Instructions 04 2017 610 48004 40f ...

Page 148: ...Spare parts 1PH808 1PH810 main motors 148 Operating Instructions 04 2017 610 48004 40f ...

Page 185: ......

Page 186: ......