Description

3.4 Design

SIMOTICS A-1FV5/1PV5 synchronous/induction motors

Operating Instructions, 03/2014, 610.45002.40

19

3.4.4

Ambient conditions

The motors are designed for ambient temperatures from -40 °C to +70 °C and installation

altitudes up to 2500 m above sea level. In the case of different ambient conditions, contact

the manufacturer.

3.4.5

Cooling

Water cooling

The motor can only be operated in a closed coolant circuit with a cooling unit. The motor is

connected to the cooling circuit using two hose connections with an outer diameter of 18 mm

at the NDE bearing shield of the motor. On motors with angled hose connections, after

loosening the locknuts they can be adjusted in both directions (preferred direction clockwise;

max. 1 revolution). After adjusting the position, the coolant connections must be fixed by

tightening the union nuts.

The inlet and outlet connections can be selected as required.

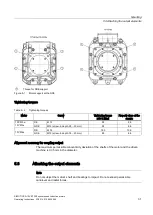

Table 3- 4

Technical data of the water cooling

Coolant

Water/anti-freeze mixture, 50/50 %

Cooling water connection

Hose connection with an outer diameter of 18

Female thread in the bearing shield Pg 13.5 /8 deep

Cooling water flow

16 l/min

Lower values will result in a derating

Max. pressure at inlet

max. 2.5 bar

Pressure loss between inlet and

outlet

< 0.2 bar for minimum cooling water flow with

1PV513/1FV513

< 0.4 bar for minimum cooling water flow with 1FV516

Min. cooling water inlet temperature T

cool

> T

ambient

– 5 K

at T

ambient

<60 °C; T

coolmin

> -40 °C

Maximum cooling water inlet

temperature, without derating

≤

55 °C,

higher values will result in derating

As coolant, only a water/anti-freeze mixture in a ratio of 50 % / 50 % is permissible. Glycol is

recommended as antifreeze. When you select a different anti-freeze, a minimum steady-

state temperature of -40 °C must be observed. Different anti-freeze agents should not be

mixed.

A filter (100 µm) must be installed in the inlet pipe to protect the motor against pollution.

Additional protection for the motor must be provided by means of a pressure relief valve

installed downstream from the filter.

If a throttle is needed to restrict the flow, it is best to install it downstream of the motor. It is

not permissible to install the throttle directly in front of the inlet because the effects of

cavitation may damage the motor.