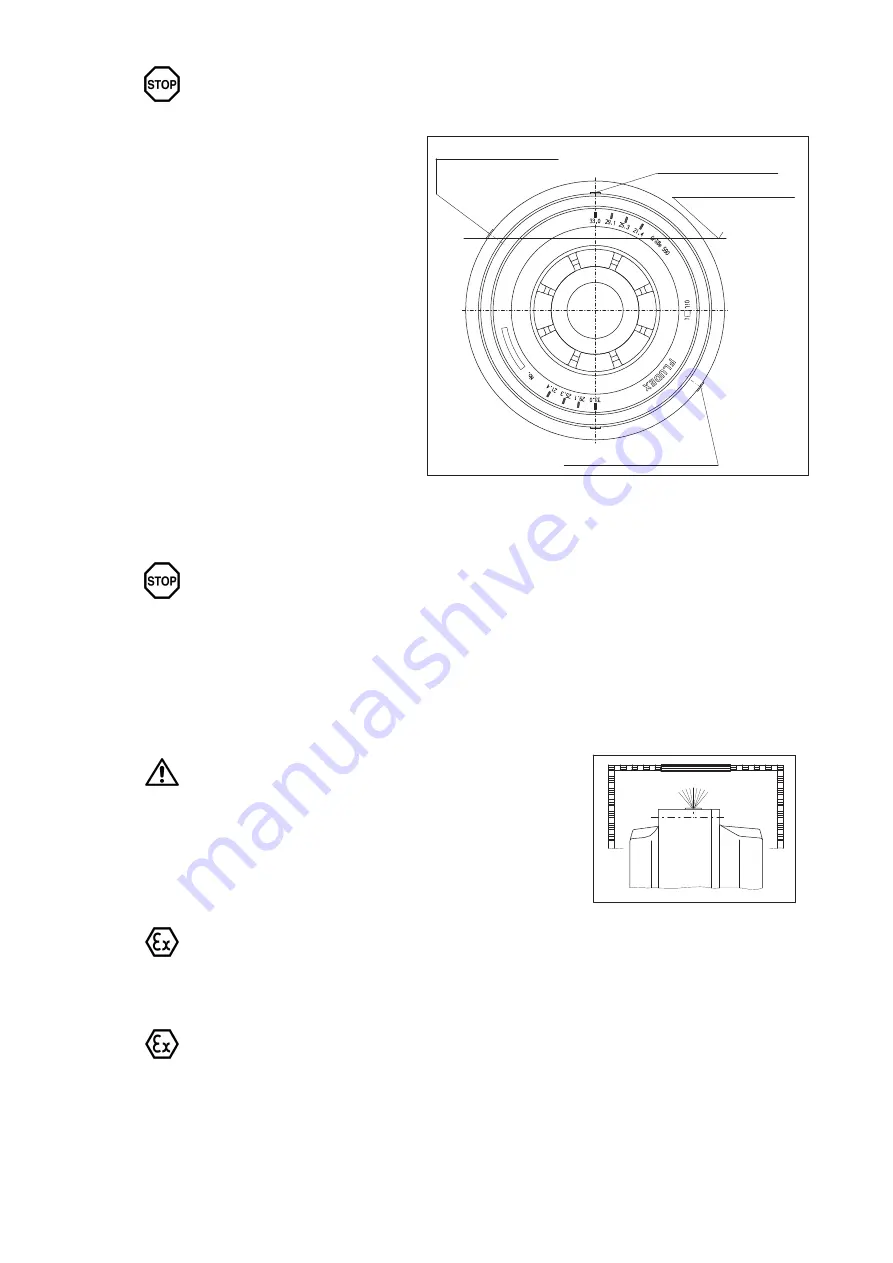

Screw plug (163) or

Filling plug (153)

maximum filling level

Fusible safety plug (103)

Fusible safety plug (103)

22

FLUDEX 4600 en

Operating instructions 10/2017

The quantity to be put into the coupling is determined in accordance with the order.

The filling quantity in litres is stamped on the coupling and specified on the

orderrelated title page.

Marking lines with litre quantities have

been cast in raised relief on the coupling

housing to assist filling the coupling and

checking the filling level.

When filling and/or checking the filling level

the mark with the required filling quantity

(in case of intermediate values the

corresponding intermediate position) must

be turned to the top position (12 o’clock).

In case of filling above the filling plug (153)

the coupling is filled with the required

quantity, if the filling level has reached the

lip of the hole for the screw plug (163).

After filling tighten filling plug (153) and screw plug (163) / fusible safety plug (103) (for tightening torques,

see section 6, item 6.6) and check coupling for leaktightness by carrying out a short test run. This may be

done by holding a clean piece of paper parallel to the turning axis and close to the rotating surface envelope

of the coupling. Any operating fluid spurting out will be visible on the paper.

FLUDEX couplings must not lose any operating fluid, as this loss may result in a rise

in slip and coupling temperature and ultimately to a fusing of the fusible safety

plug (103).

Then finally fit the clutch guard to prevent unintentional contact.

Faults in the drive (e.g. locking of the output side) may result in the coupling overheating. If the fusing

temperature of the fusible safety plug is reached, the insert will melt and the hot operating fluid (oil, water)

escape. The coupling protection must therefore be so designed as to also guarantee protection against

operating fluid spurting out without appreciably impairing the ventilation of the coupling. The fusible safety

plugs (103) and the filling plugs (153) should be accessible.

Rotating parts must be secured by the purchaser

against accidental contact. The coupling protection

must also protect against spurting hot operating

fluid without appreciably impairing ventilation

(see also information on the coupling).

If it is to be used below ground in potentially explosive areas, the coupling, which is

made of aluminium, must be provided with a robust casing to preclude the risk of

ignition from e.g. friction, impact or friction sparks.

The depositing of heavy metal oxides (rust) on the coupling housing must be

precluded by the casing or other suitable precautions.

Couplings to be used in potentially explosive areas are designed with the fusible

safety plugs (103) permitted for the temperature class. The coupling is marked with

the temperature class of the fusible safety plug (103).

It must be ensured that the drive shuts off not later than 5 minutes after the fusible

safety plug (103) is fused.

Summary of Contents for Flender FLUDEX 4600 FAD Series

Page 2: ......