Mechanical properties of the motors

3.5 Bearing version

1FT7 Synchronous Motors

Configuration Manual, (PFT7S) 01/2009, 6SN1197-0AD13-0BP2

63

Technical data for sealing air connection

●

Connecting thread M5

●

Gauge pressure from 0.05 mbar to 0.1 bar

●

Compressed air must be dried and cleaned (entrained particles > 3 μm not permissible)

Sealing of the motor shaft

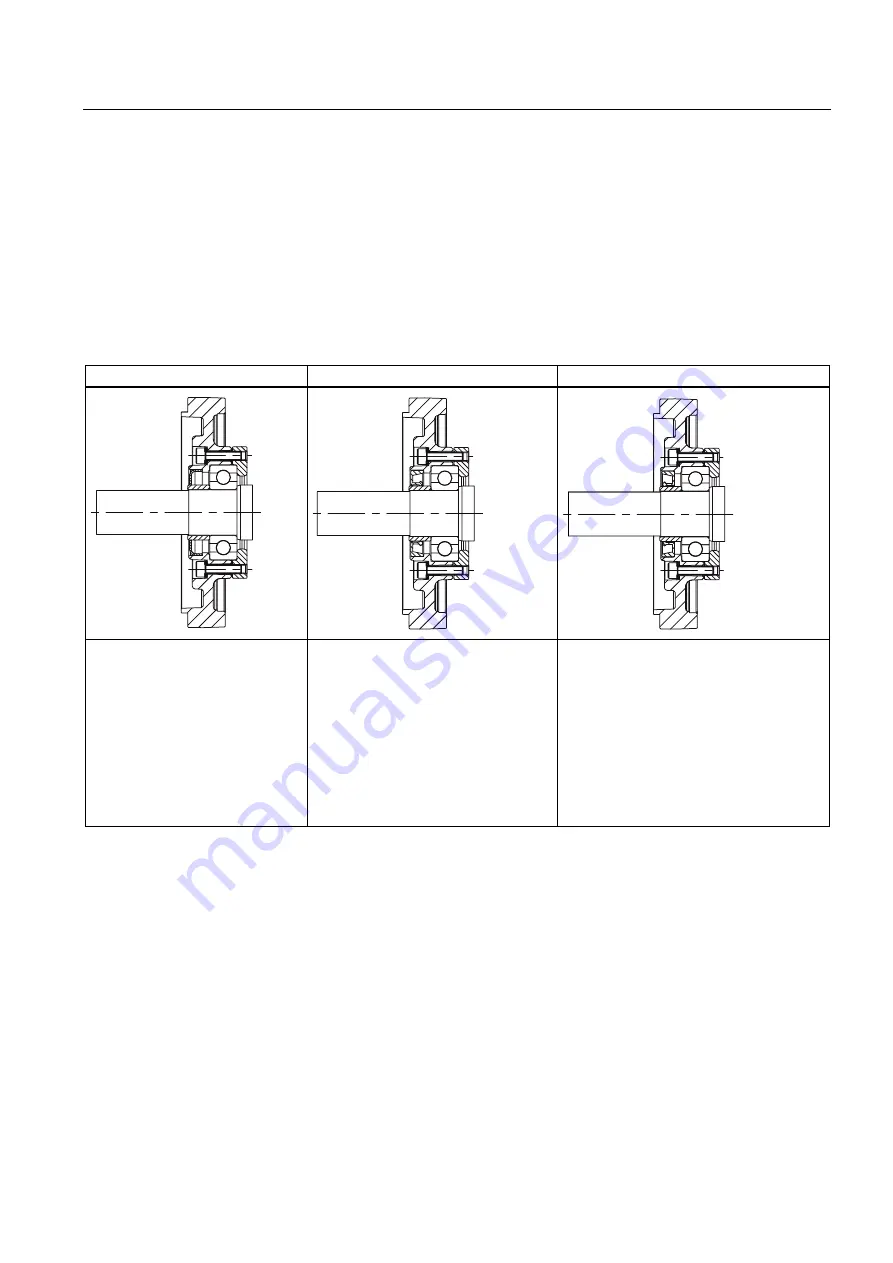

Table 3- 10 Motor shaft sealing

IP64

IP65

IP67

Labyrinth seal

It is not permissible that there is

any moisture in the area around

the shaft and the flange.

Note:

For IP 64 degree of protection it is

not permissible that liquid collects

in the flange. Shaft outlet is not

dust-tight

Radial shaft sealing ring without annular

spring

Shaft outlet seal to protect against

spray water and cooling-lubricating

medium. It is permissible that the radial

shaft sealing ring runs dry. Lifetime

approx. 25000 h (nominal value).

For IP65 degree of protection it is not

permissible that liquid collects in the

flange.

Radial shaft sealing ring

For gearbox mounting (for gearboxes that

are not sealed) to seal against oil.

The sealing lip must be adequately cooled

and lubricated by the gearbox oil in order to

guarantee reliable function.

Lifetime approx. 10000 h (nominal value).

If a radial shaft sealing ring runs dry, then

this has a strong negative impact on the

functionality and the lifetime.

3.5

Bearing version

The 1FT7 motors are equipped with greased-for-life deep-groove ball bearings. The location

bearing is at the DE.

Summary of Contents for 1FT7 Series

Page 2: ......

Page 12: ...Preface 1FT7 Synchronous Motors 12 Configuration Manual PFT7S 01 2009 6SN1197 0AD13 0BP2 ...

Page 251: ......