17

Glossary

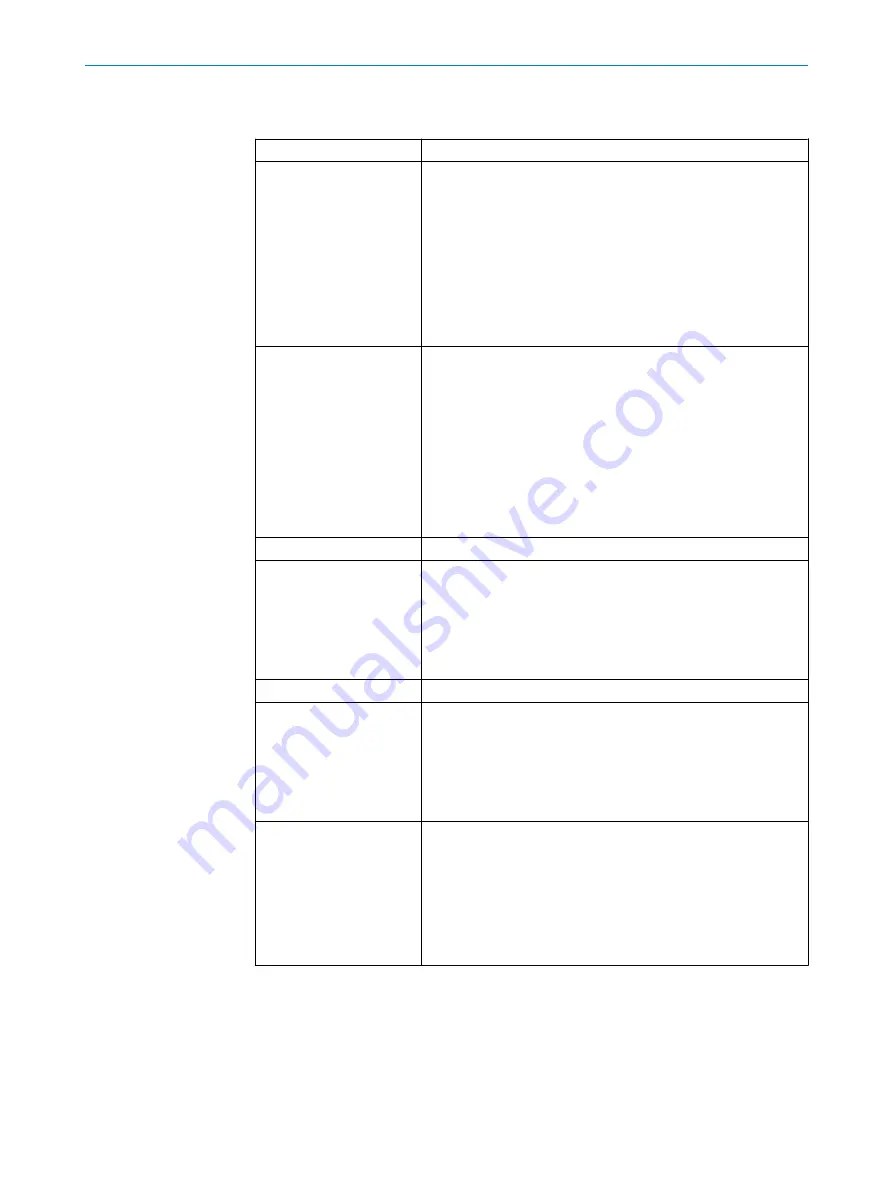

AGV

Automated guided vehicle

Control input

A control input receives signals, e.g. from the machine or from the

control. Use of control inputs is how the protective device receives

information about the conditions at the machine, e.g., if there is a

change of operating mode. If the protective device is configured

appropriately, it will activate a different monitoring case after

receiving a new control input.

The control input information must be transmitted reliably. Gener‐

ally, at least 2 separate channels are used to do this.

Depending on the device, a control input can be realized as a sta‐

tic control input or a dynamic control input.

Dangerous state

A dangerous state is a status of the machine or facility, where peo‐

ple may be injured. Protective devices prevent this risk if the

machine is operated within its intended use.

The figures in this document always show the dangerous state of

the machine as movement of a machine part. In practice, there

are different dangerous states, such as:

•

Machine movements

•

Electrical parts

•

Visible and invisible beam

•

A combination of multiple hazards

EDM

External device monitoring

Electro-sensitive protective

device

An electro-sensitive protective device is a device or system of

devices for safety-related detection of people or parts of the body.

It is used to protect people from machines and facilities that pose

a risk of injury. It triggers the machine or facility to adopt a safe

state before a person is exposed to a hazardous situation.

Examples include safety light curtains and safety laser scanners.

ESPE

Electro-sensitive protective device

EtherNet/IP

EtherNet/IP™ (EtherNet Industrial Protocol) is an Ethernet-based

network used in industrial automation.

EtherNet/IP™ implements the CIP™ (Common Industrial Protocol)

based on the Ethernet and TCP/IP protocol family.

EtherNet/IP™ with the CIP Safety™ protocol extension is also suit‐

able for safety-related data communication.

External device monitoring

The external device monitoring (EDM) monitors the status of down‐

stream contactors.

In order to use external device monitoring, positively guided con‐

tactors must be used to switch off the machine. If the auxiliary

contacts of the positively guided contactors are connected to the

external device monitoring, the external device monitoring checks

whether the contactors switch correctly when the OSSDs are

switched off.

GLOSSARY

17

8023152/160F/2019-11-14 | SICK

O P E R A T I N G I N S T R U C T I O N S | outdoorScan3 Core I/O

145

Subject to change without notice