Operating Instructions

Chapter

6

TPS

8021799/2017-09-26

Operating Instructions | SICK

53

Subject to change without notice

Commissioning

6.5.2

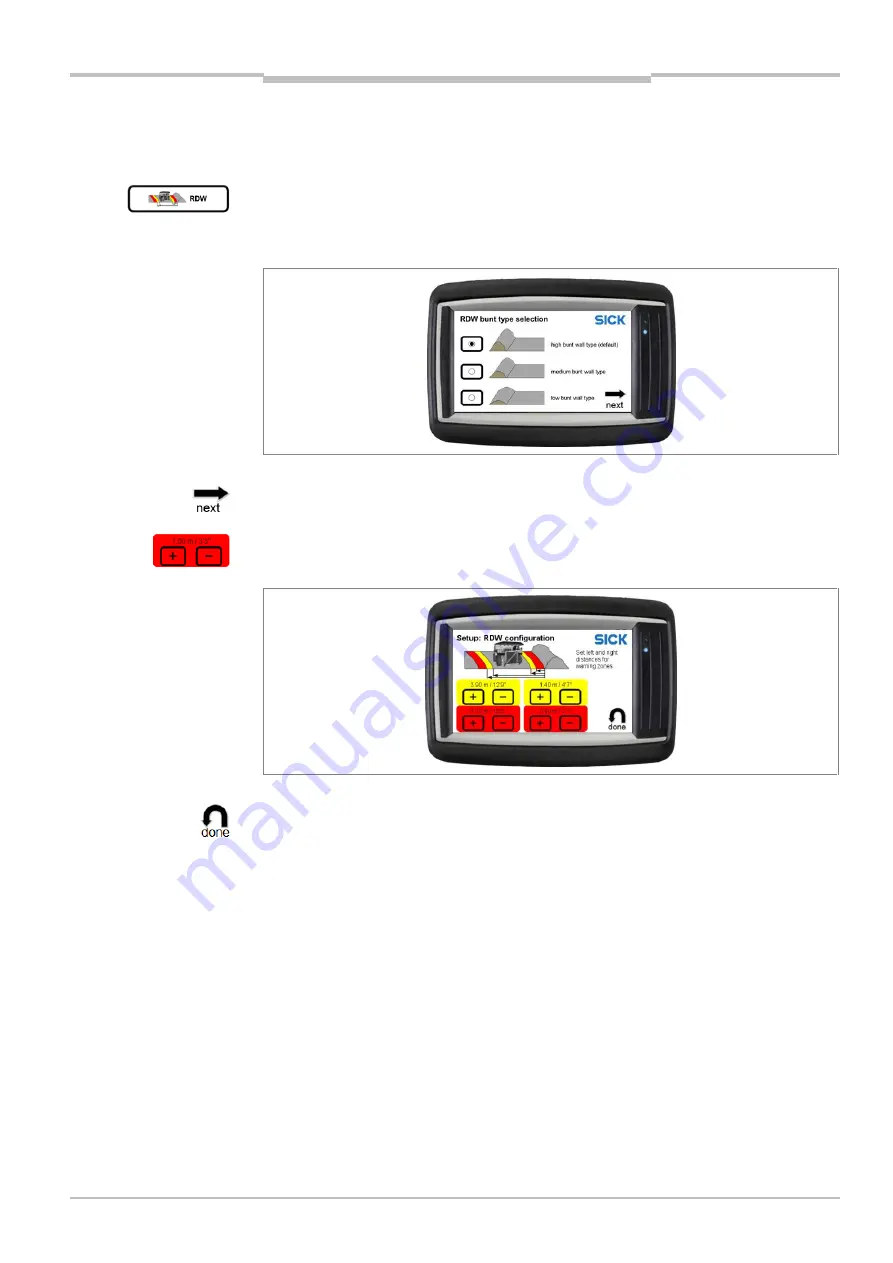

RDW setup

The RDW warning zones are defined relatively to the left road limitation

Click on the

RDW

icon.

1. Choose the bunt wall type according to individual mine site situation.

2. Confirm the adjusted warning zone using the

next

icon.

3. Adjust the warning zones for

RDW

accordingly using the plus/minus icon for the yellow

and red warning zones.

4. Confirm the adjusted warning zone using the

done

icon. The parameters are

permanently saved in the system.

You will then be taken back to the supervisor setup page with the individual setup steps

for the warning zones.