ENGLISH

SHINDAIWA OWNER’S/OPERATOR’S MANUAL

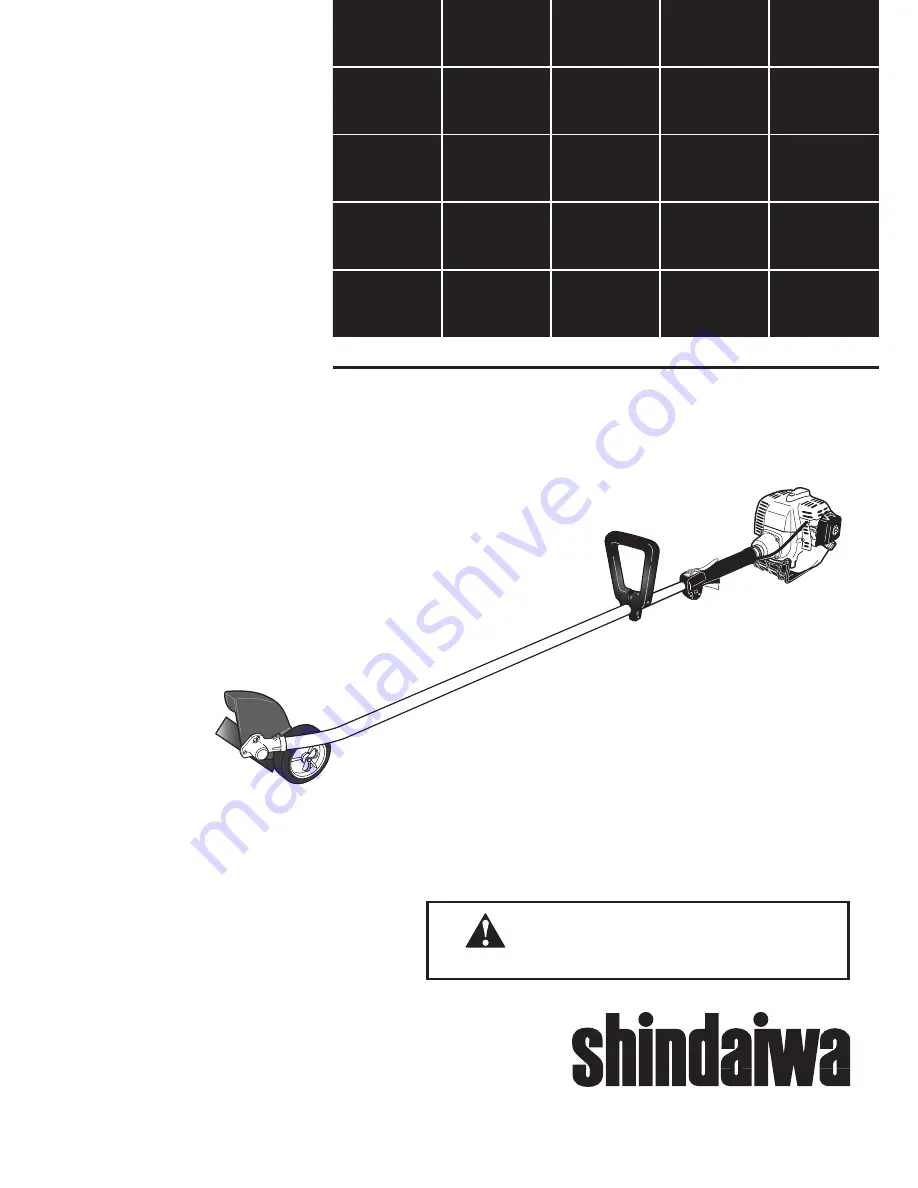

LE231/EVC LAWN EDGER

Part Number 62719-94310 Rev. 11/06

Minimize the risk of injury to yourself and others!

Read this manual and familiarize yourself with the

contents. Always wear eye and hearing protection

when operating this unit.

WARNING!

LE231