14U10/15

14U20/25

7

7-1

7-2

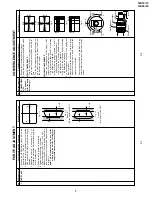

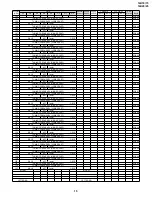

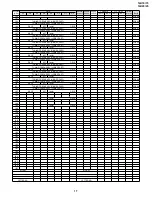

CONVERGENCE ADJUSTMENT

No.

Adjusment point

Conditions/Adjusting pr

ocedure

W

a

vef

orm or other

s

CONVERGENC

ADJ.

(

T

o

be done

after the purity

adjustment.)

1

RGB

BGR

R

G

B

R

G

B

B

G

R

B

G

R

R G B

BGR

Lacquer

Wedge "a"

Wedge

"b"

Wedge

"c"

About

100

Deg

About

100

Deg

4-pole magnet

6-pole magnet

CRT neck

20cm

40cm(14")

(21")

Lacquer

Purity magnet

Fig. a

Fig. b

Fig. c

Fig. d

1.

Receive the "Crosshatch Pattern" signal.

2.

Using the remote controller

, call NORMAL mode

.

ST

A

TIC CONVERGENCE

1.

T

u

rn

the 4-pole magnet to a proper opening an-

gle in order to superpose the blue and red col-

ours.

2.

T

u

rn

the 6-pole magnet to a proper opening an-

gle in order to superpose the green colour over

the blue and red colours.

DYNAMIC CONVERGENCE

1

.

Adjust the convergence on the fringes of the

screen in the following steps.

a)

Fig.

a:

Dr

iv

e the w

edge at point "a" and s

wing

the deflection coil upward.

b)

Fig.

b:

Dr

iv

e the w

edge at points "b" and "c"

and swing the deflection coil downward.

c)

Fig.

c:

Dr

iv

e the "c" w

edge deeper and s

wing

the deflection coil rightward.

d)

Fig.

d:

Dr

iv

e the "b" w

edge deeper and s

wing

the deflection coil leftward.

2.

Fix all the w

edges on the CR

T and apply glass

tape over them.

3.

Apply lacquer to the deflection y

ok

e loc

k scre

w

,

magnet unit (pur

ity

, 4-pole

, 6-pole magnets) and

magnet unit loc

k scre

w

.

Finally received the Red-only and Blue-only sig-

nals to make sure there is no other colours on the

screen.

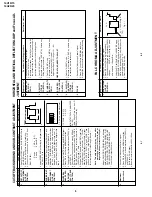

PURITY ADJUSTMENT

No.

Adjusment point

Conditions/Adjusting pr

ocedure

W

a

vef

orm or other

s

PURITY ADJ

.

1

.

Receiv

e the GREEN-ONL

Y signal.

Adjust the

beam current to ~ 500

µ

A.

2.

Maintain the purity magnet at the zero magnetic

field and keep the static convergence roughly

adjusted.

3

.

Obser

v

e

the points a, b

, as sho

wn in Fig.

1-1

through the microscope

. Adjust the landing to the

A rank requirements.

4.

Orient the raster rotation to 0 eastward.

5.

Tighten up the deflection coil scre

ws

.

»

Tightening

torque:

108

±

20 N (11

±

2 kgf)

6.

Mak

e sure the CR

T cor

ners landing meet the A

rank requirements. If not, stick the magnet sheet

to correct it.

Note:

This adjustment must be done after

warming up the unit for 30 minutes or

longer with a beam current over 500

µ

A.

1

a

b

A

B

A

B

A = B

A = B

Rank "A"

(On the right of the CRT)

Rank "A"

(On the left of the CRT)

Fig. 1-1

Fig. 1-2

Fig. 1-3

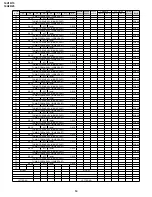

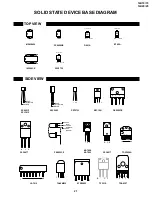

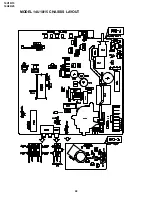

Summary of Contents for 14U10

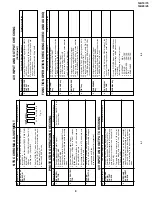

Page 22: ...14U10 15 14U20 25 22 MODEL 14U10 15 CHASSIS LAYOUT ...

Page 23: ...14U10 15 14U20 25 23 MODEL 14U20 25 CHASSIS LAYOUT ...

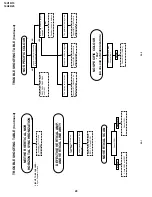

Page 24: ...14U10 15 14U20 25 14U10 15 14U20 25 24 25 BLOCK DIAGRAM 1 3 MODEL 14U10 15 MAIN BLOCK ...

Page 25: ...14U10 15 14U20 25 14U10 15 14U20 25 BLOCK DIAGRAM 2 3 MODEL 14U20 25 MAIN BLOCK 26 27 ...

Page 26: ...14U10 15 14U20 25 28 BLOCK DIAGRAM 3 3 MODEL 14U20 25 HEADPHONE BLOCK CRT BLOCK ...

Page 27: ...14U10 15 14U20 25 29 WAVEFORMS ...

Page 31: ...14U10 15 14U20 25 33 M E M O ...

Page 43: ...Ref No Part No Description Code Ref No Part No Description Code 49 14U10 15 14U20 25 ...