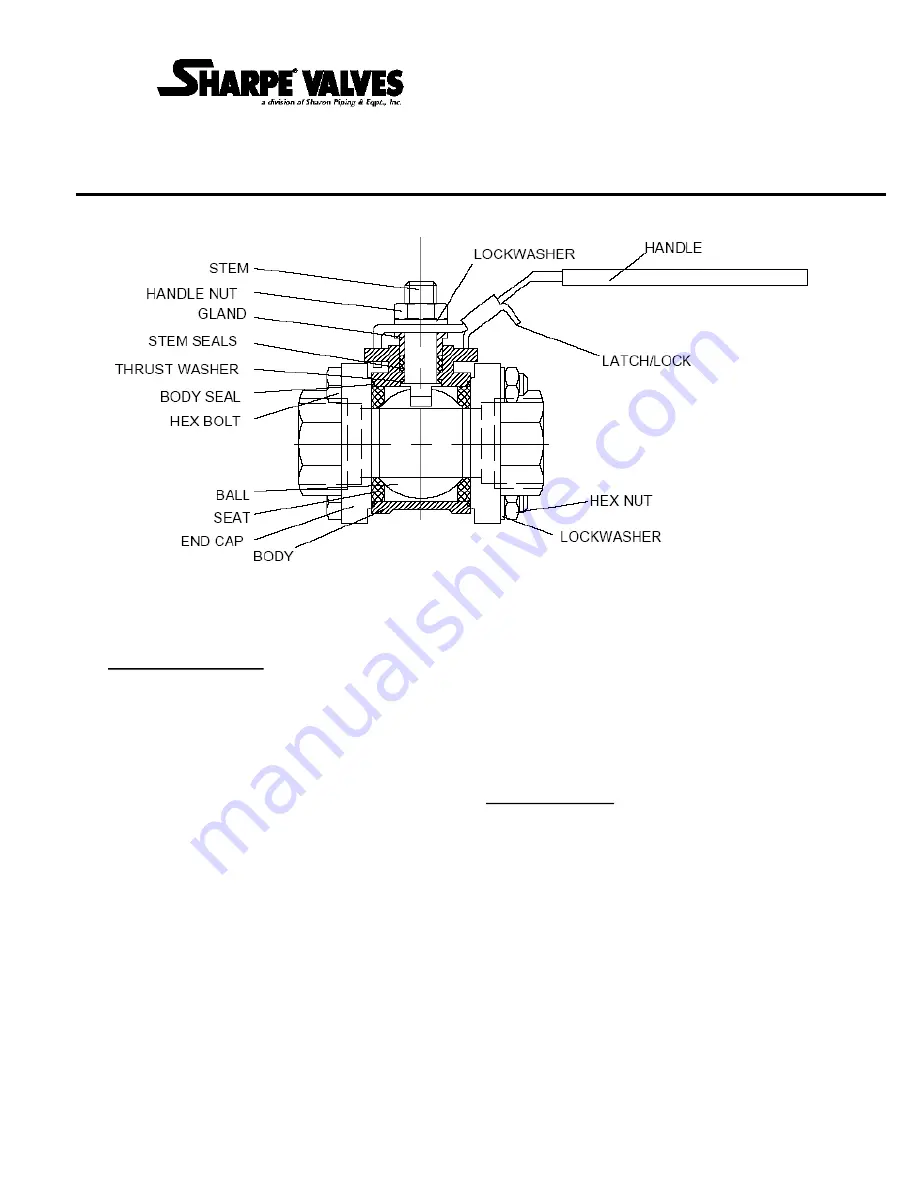

3-PIECE FULL PORT BALL VALVE

–

MODELS 53034 & 53036

INSTALLATION, OPERATION, AND MAINTENANCE INSTRUCTIONS

IM-53-1 (6/04)

INSTALLATION

:

These valves may be installed in the pipeline in

any orientation or position, using good piping

practice. For threaded end valves, use a

suitable joint compound or TFE tape on pipe

threads for ease of fit-up.

Welding End Valves:

Socket weld and butt weld end valves must be

partially disassembled to prevent heat damage

during welding of the soft plastic seats and seals

in the valve. Prior to disassembly, the valve

may be temproarily fitted in line, and the ends

tack-welded to the piping for alignment

purposes.

With the valve in the open position, remove the

body hex nuts and lockwashers, and the body

hex bolts. Carefully lift out the center section,

making sure that the seats and body seals are

held in position. Place the center section in a

clean area where it will not be damaged, and

complete the welding of the end caps to the

piping.

When the welds are cool to the touch, reinstall

the center section of the valve between the body

end caps. Take care that the seats and seals

are in place, and have not been damaged. Re-

install the body bolting, and tighten following the

“Assembly” instructions on the following page.

OPERATION:

These are quarter-

turn (90° rotation) ball valves,

and are normall fitted with a latching lever

handle for manual operation. The handles also

contain travel stop tabs at the open and closed

positions. To open the valve, lift the latch/lock

slider up, and turn the handle clockwise. To

close the valve, lift the latch/lock and turn the

handle counterclockwise.

For valves fitted with power actuators, operating

instructions are contained in the manuals

supplied with the actuator and accessories.