Manual – XFE24A EtherCAT Fieldbus Interface

25

6

Control of the MOVIAXIS® multi-axis servo inverter

Operating Behavior on EtherCAT

6

Operating Behavior on EtherCAT

This section describes the basic behavior of the servo inverter on the EtherCAT system

when controlled via permanently configured PDOs for fieldbus communication.

6.1

Control of the MOVIAXIS

®

multi-axis servo inverter

The MOVIAXIS

®

multi-axis servo drive is controlled via the permanently configured

PDOs, which are up to 16 I/O words in length. When using an EtherCAT master, the pro-

cess data words are directly mapped in the process image and can so be addressed di-

rectly by the control program.

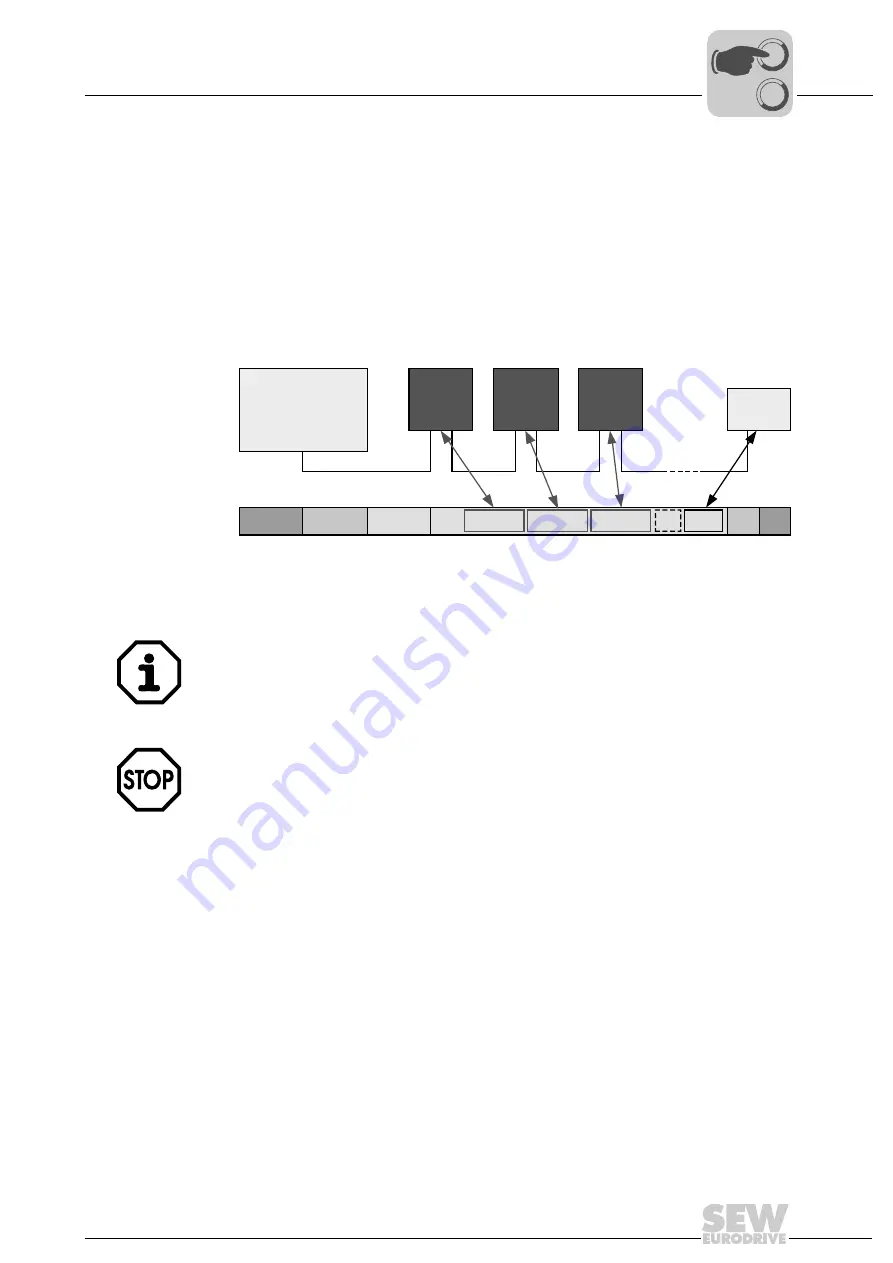

61375AXX

Figure 9: EtherCAT with SEW drives

SEW

Drive

Ether

CAT

Ethernet

Header

Frame

Header

EtherCAT

Header

Data

...

EtherCAT

M aster

SEW

Drive

SEW

Drive

FCS

I/O

Drive 1 Drive 2 Drive 3

For more information about controlling via the process data channel, in particular re-

garding the configuration of the control and status words, refer to the "MOVIAXIS

®

Multi-

Axis Servo Inverter" project planning manual.

For proper operation of synchronized applications, timing requirements must be met by

the master depending on the synchronization mechanism.

•

Synchronization via Distributed Clock (DC):

The process data telegram must arrive shortly before the DC. Beckhoff recommends

a maximum time of 10 % (in relation to the DC cycle) before the DC.

•

Synchronization via synchronized process data:

The MOVIAXIS

®

servo system can handle a maximum jitter of the EtherCAT process

data telegram (setpoints of the master, etc.) of ± 40 µs. If this jitter limit is exceeded,

a synchronous processing is no longer guaranteed. Please check the synchroniza-

tion quality of your EtherCAT master if problems occur.

0

0

I

Summary of Contents for 1821 2492

Page 2: ...SEW EURODRIVE Driving the world...

Page 66: ......