42

SESAMO

DUALCORE

Maintenance: the maintenance interval on the DUALCORE SERIES automated system is

determined on the basis of the use intensity of the automation and the conditions of use.

In high-traffic systems

(entrances to airports, supermarkets, shopping centers, refreshment

rooms in motorway parking areas, etc.) or operating in particularly severe conditions

(exposure to corrosive agents, proximity to the sea, very windy areas, leaves subject to

frequent impacts with moving objects such as supermarket trolleys, etc.) it is recommended to

carry out

half-yearly

scheduled maintenance by a specialized technician.

In low traffic systems

(small businesses, private offices, homes, operating rooms, etc.),

scheduled maintenance should be carried out

yearly

by a specialized technician.

Maintenance manual

The following checks and procedures should be carefully performed during a scheduled

maintenance intervention carried out by an authorized technician:

❑

Disconnect the mains power supply using the bipolar switch upstream of the

automated system.

❑

Open the automated system by removing the cover.

❑

Disconnect the batteries

❑

Check the tightness of the screws of the carriages and of the components installed

inside the box.

❑

Check the wiring connections between the accessories, the sensors and the

electronic control unit.

❑

Clean the slide rail with a cloth (No detergent products) and check its integrity.

❑

Check the smoothness of the window, its general conditions (evaluate any out of

square caused by impacts) and above all that a minimum space of 5 mm remains

between the floor and the leaf in order to guarantee correct sliding even in case of

strong thermal expansion of the window.

❑

Clean the carriage wheels and check their wear; replace if necessary.

❑

If necessary, grease the slide rail with a thin layer of bearing grease.

❑

Check the wear state of the belt and grease if necessary.

❑

Reconnect the automated system to the mains power supply and to the batteries.

❑

Check the wear and proper functionality of the floor guide and if necessary grease

or replace.

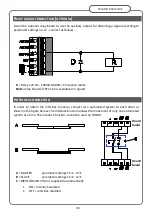

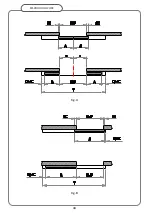

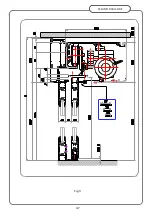

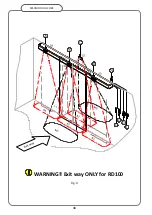

Summary of Contents for DUALCORE LH100

Page 1: ...LH100 LH140 RD100 ENGLISH AUTOMATED SYSTEMS FOR SLIDING DOORS INSTALLATION MANUAL ...

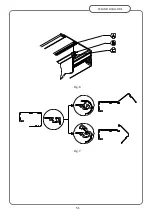

Page 44: ...44 SESAMO DUALCORE Fig A Fig B ...

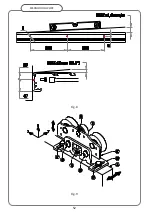

Page 45: ...45 SESAMO DUALCORE Fig 1 ...

Page 46: ...46 SESAMO DUALCORE Fig 2 ...

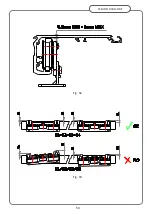

Page 47: ...47 SESAMO DUALCORE Fig 3 ...

Page 48: ...48 SESAMO DUALCORE WARNING Exit way ONLY for RD100 Fig 4 ...

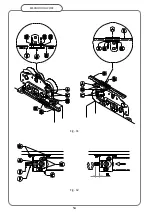

Page 49: ...49 SESAMO DUALCORE Fig 5 ...

Page 50: ...50 SESAMO DUALCORE Fig 5 A ...

Page 51: ...51 SESAMO DUALCORE Fig 6 Fig 7 ...

Page 52: ...52 SESAMO DUALCORE Fig 8 Fig 9 ...

Page 53: ...53 SESAMO DUALCORE Fig 9a Fig 10 ...

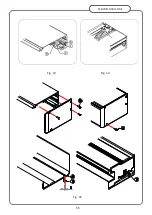

Page 54: ...54 SESAMO DUALCORE Fig 11 Fig 12 ...

Page 55: ...55 SESAMO DUALCORE Fig 13 Fig 14 Fig 15 ...

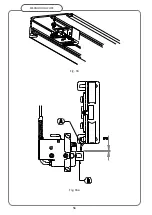

Page 56: ...56 SESAMO DUALCORE Fig 16 Fig 16a ...

Page 57: ...57 SESAMO DUALCORE Fig 17 Fig 17a ...

Page 58: ...58 SESAMO DUALCORE Fig 18 Fig 19 Fig 20 ...

Page 59: ...59 SESAMO DUALCORE Fig 21 Fuses 6 3A T J ...

Page 60: ...60 SESAMO DUALCORE Fig 22 ...

Page 61: ...61 SESAMO DUALCORE Fig 23 1 Fig 23 2 ...

Page 62: ...62 SESAMO DUALCORE Fig 24 PARAMETER 30 1 ...

Page 63: ...63 SESAMO DUALCORE Fig 25 PARAMETER 30 1 Exit way ...

Page 64: ...64 SESAMO DUALCORE Fig 25 A ...

Page 65: ...65 SESAMO DUALCORE Fig 26 ...

Page 66: ...66 SESAMO DUALCORE Fig 27 PARAMETER 31 1 ...

Page 67: ...67 SESAMO DUALCORE Fig 28 PARAMETER 31 0 ...

Page 68: ...68 SESAMO DUALCORE Fig 29 ...

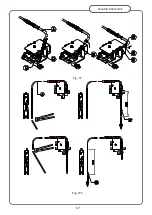

Page 69: ...69 SESAMO DUALCORE Fig 30 Fig 31 ...

Page 71: ...71 SESAMO DUALCORE Fig 33 ...

Page 72: ...72 SESAMO DUALCORE Fig 34 ...