FlexPS Product Guide

Page 23

2

Installation

Installing the sensor cable

Cable handling rules

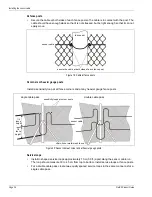

The FlexPS sensor cable converts minute vibrations in the fence fabric into electrical signals. Any

damage to the cable from mishandling or poor installation practices will have a negative effect on

the system’s performance.

•

DO NOT allow the cable to fall off the cable reel during installation.

•

DO NOT bend, twist, jerk, knot, or kink the sensor cable. Sensor cable MUST NOT be nicked,

or scraped.

•

Avoid tight turns in the sensor cable, the smallest allowable bend radius for MEX sensor cable

is 4 cm (1.5 in.) for Mark 2 sensor cable is 7.5 cm (3 in.) and for Armour-FLEX cable is 15 cm

(6 in.).

•

DO NOT place objects on the sensor cable or allow anyone to stand or walk on the cable.

•

DO NOT apply excessive tension to the sensor cable at any time.

•

When using cable ties to attach the sensor cable to a fence, install the ties by hand and pull

them hand-tight until snug.

•

DO NOT use mechanical tighteners to attach cable ties to a fence.

•

DO NOT allow the sensor cable to be pinched between the fence and a fence post, or any

other object.

•

When attaching the sensor cable to a flat mounting surface, use fasteners that hold the cable

firmly against the surface without squeezing, crimping or distorting the cable in any way.

•

DO NOT use a staple gun to attach sensor cable to a wall.

•

Keep the ends of the sensor cable clean and dry. For Mark 2 cable, if water enters the loose

tube it can cause corrosion and potentially freeze in the winter, thereby having a negative

effect on detection sensitivity.

Note

The number of cable passes required on a fence depends on the

height of the fence, the type of fence, and the required level of

security (see

Fence height recommendations on page 15

Note

Mark 2 sensor cable must be conditioned before it is attached to the

fence.