METIS M311 / M322 / H311 / H322 (17-pin)

SensorTools Software

39

dark offset by several degrees, this indicates the lens was not darkened 100% and ambient light

has penetrated. Then repeat the step.

-

2C:

Finally, adjust the 2-color temperature until the temperature value of the calibration source

is shown correctly.

- H3 models:

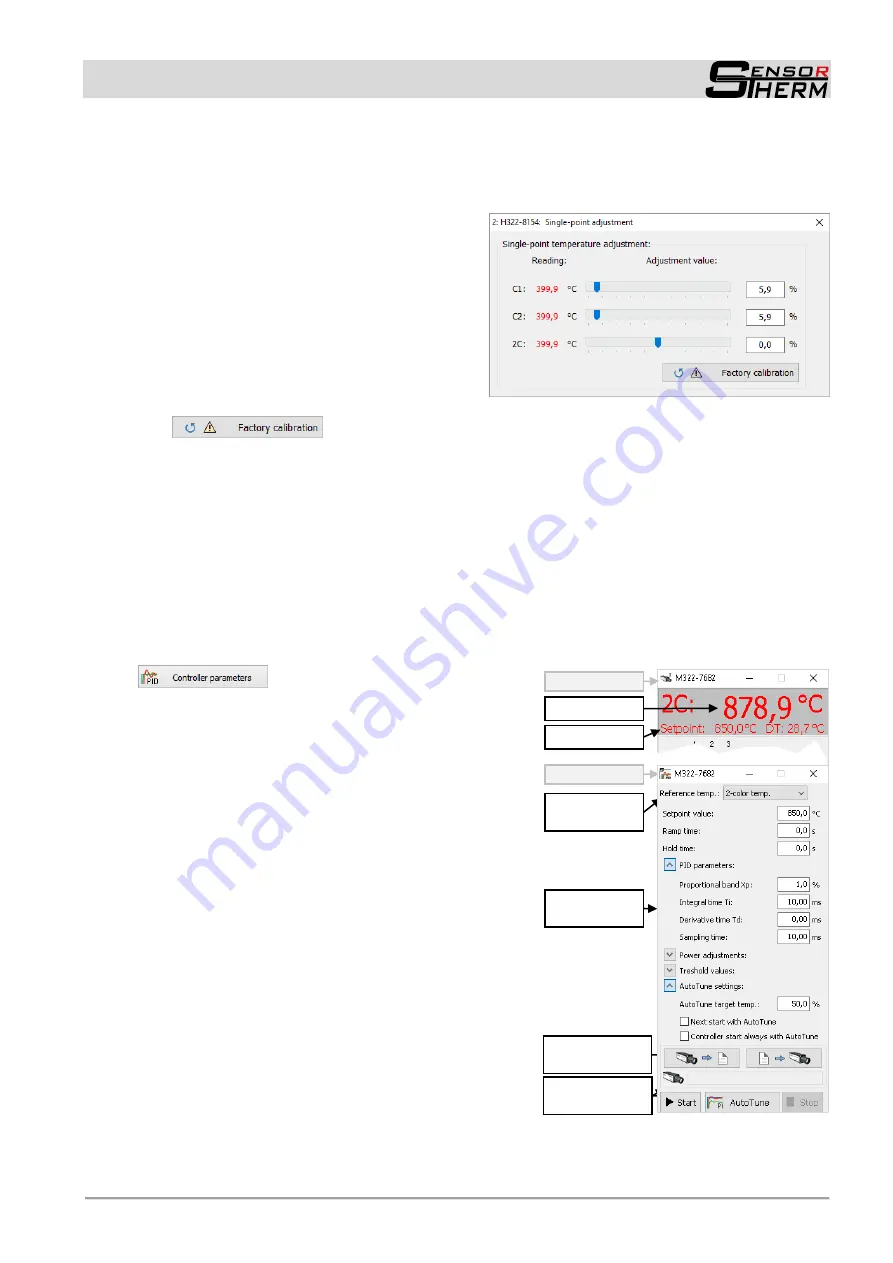

- Move the sliders one by one for channel 1

(C1), channel 2 (C2) and finally for the ra-

tio temperature (2C) until the temperature

value of the calibration source is measured

correctly.

-

: The process takes between one and two minutes. If anything goes wrong,

for example the calibration source does not work smoothly, nevertheless calibration values are

written into the pyrometer. In this case the process should be performed again or the device should

be reset to factory settings, this sets all calibration values back to 0.0%.

7.2.4 PID Controller

M3 and H3 pyrometers with a 17-pin connector are equipped with an integrated PID controller. At this,

the temperature signal is converted into a control signal via a PID controller software. A setpoint value

and the necessary PID parameters are set to trigger a corresponding control value output. At the analog

output 2, the control signal is provided, via display and analog output 1 the current temperature reading

is available (factory setting, assignment can be changed in the pyrometer port settings, see

Parame-

ters / Settings

Device Settings and Configuration

).

An integrated PID controller is auto-

matically detected by the software and activates the button

for the controller configuration.

A setpoint and the necessary PID control parameters are

entered directly in the software and transferred to the py-

rometer by pressing the ENTER or tabulator key, control

parameters also can be changed during running control

mode. Invalid value entries are automatically corrected to

the next possible.

Control parameters:

Always visible parameters:

- Reference temperature:

selects the temperature

that is displayed in the control window (same function

as in the control window)

- Setpoint value:

Setpoint specification

- Ramp time

(in 100 ms)

:

The setpoint temperature

will be approached by increasing the temperature

with a uniform gradient of the temperature within the

entered time (the setpoint temperature in the grey

field above can show updated ramp temperatures if

the buffer mode settings in the data collection set-

tings (see

) are set to “with state information”).

- Hold time:

when reaching the desired value, the set-

point value in can be maintained at the current value.

The control process stops automatically after the hold

time is elapsed.

Start / Stop con-

trol process

Measured temp.

Setpoint display

Automatically find

control values

Setpoint specifi-

cation

Control parame-

ters

Control window

Controller window