BODYSHOP/WORKSHOP HEADLAMP

BEAM SETTER

Model no:

HBS2001

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAfETY

8

DO NOT

allow unqualified persons to operate the HBS.

8

DO NOT

use the HBS in direct sunlight.

8

DO NOT

splash the HBS with water or any other liquid.

9

do ensure the work area is well ventilated.

9

do ensure that there is good lighting.

9

do apply handbrake on vehicle.

9

do avoid sudden changes in temperature.

9

do avoid sudden vibration.

2. INTRODucTION

S

uitable for pre-MOT inspection in garages and bodyshops. Utilises same optical box and aiming screen as fitted to our MOT approved

headlamp beam setter. Fixed aiming screen. Internal analogue lUX meter for accurate light intensity measurement. Suitable for all types of

cars and light commercial vehicles. Fitted with fixed column and

rubber wheels.

3. SPEcIfIcATION

Height ..........................................................................1750mm

Width .............................................................................660mm

length ...........................................................................620mm

Maximum height of beam measurement .....................1500mm

Minimum height of beam measurement ........................220mm

Focal length ...................................................................500mm

4. ASSEMBLY

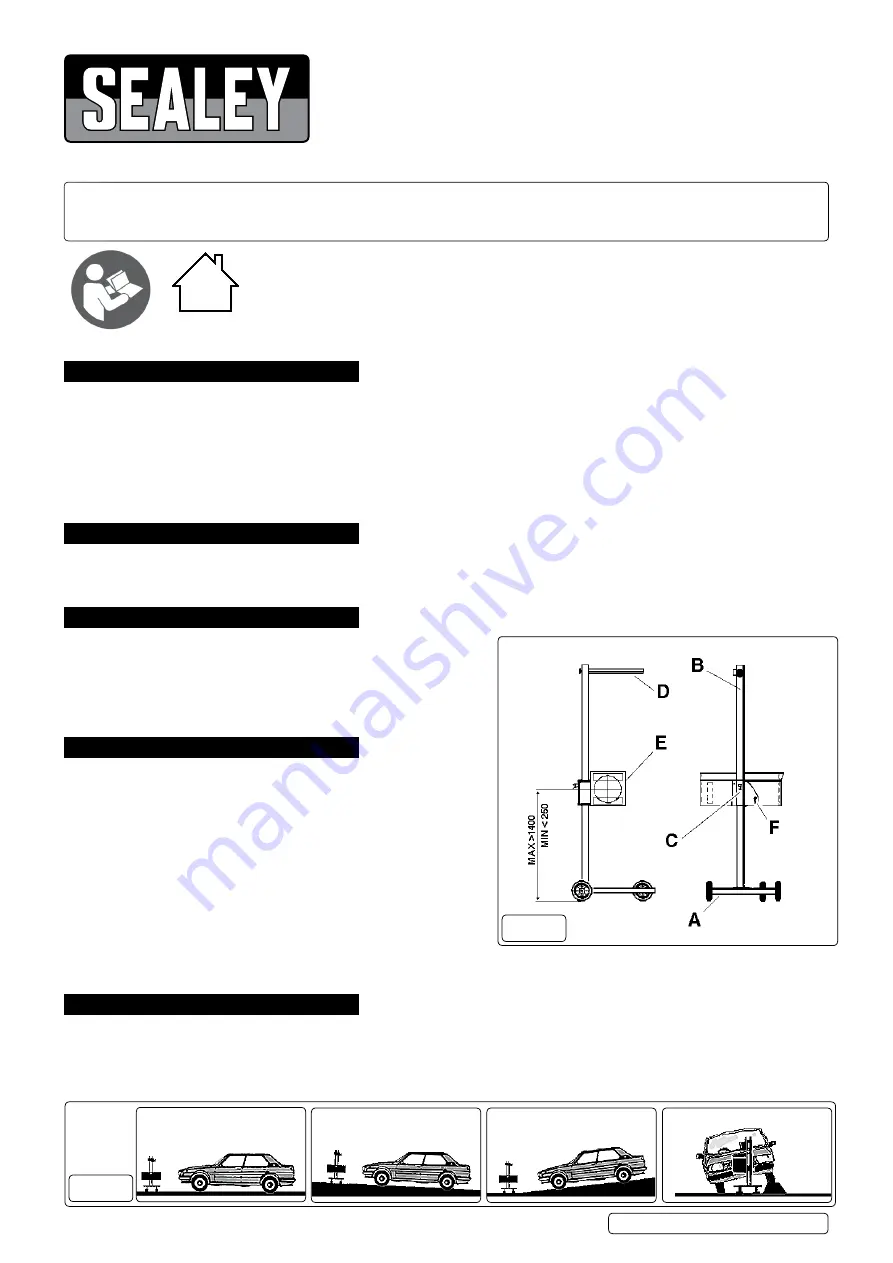

4.1.

Figure 1

A ......................................................................................BASe

B ................................................................................ColUMn

C ...............................................VeRTICAl SlIdInG SYSTeM

d .....................................................................MIRRoR-VISoR

e .................................................................oPTICAl SYSTeM

F ..................................................................... leVeR SCReW

4.2.

Attach column B to base A using nuts, bolts and washers provided.

Column should be positioned so that optical system mounting

plate on sliding system C is facing the single wheel.

4.3.

Attach mirror-visor d to mounting plate at the top of column B with the

two screws provided (in end of visor).

4.4.

Fit the optical system e to the vertical sliding system C using the two screws and washers provided (fit lever screw F and larger washer

over slotted hole).

5. PREPARATION fOR uSE

5.1.

Working Surface

5.1.1.

Position the vehicle on the designated headlamp aim standing area.

5.1.2.

When positioning the HBS ensure the floor is perfectly even and level.

5.1.3.

If this is not possible the vehicle and HBS must be on the same slope, which must not exceed 0.5º.

5.1.4.

Headlights must not be checked where surface angle exceeds 0.5º (see fig. 2).

fig.1

fig.2

HBS2001 Issue 3 (HF) 14/08/18

Original Language Version

© Jack Sealey limited

Refer to

instructions

Indoor use only

OK

0.5

0

MAX

NO

NO