Assembly

30

08.00 | NSE3 138, NSE-T3 138 | VERO-S quick-change pallet system | en |

1152197 -NSE3 NSE-T3

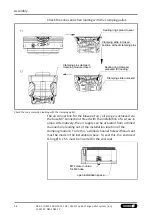

Alternative connection option:

Two side G1/8" connections which are free when the lower

centering diameter Ø 110 H6 is used. In this case, the bottom

openings must be sealed. To do so, insert the Ø 9 x 1.5 O-rings into

the module and seal the bottom direct connections against the flat

support surface.

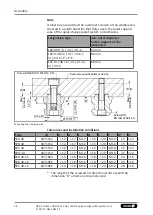

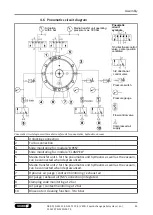

4.3.5 NSE3 138-P, NSE3 138-P-K

Fastening in the installation space preferred with 5 M8 screws and

a fitting screw M8.

Alternative: Fastening with 6 M8 screws.

The assembly module can be positioned by means of two

centering diameters of the installation space:

Ø 110 H6

in the lower range. For partial and full installation.

Ø 138 H6

in the upper range.

The exact position orientation is done with a fitting screw with a

diameter of Ø 9 f7 x 5 mm. Precise alignment and positioning of

the quick-change pallet system requires that the fitting bore Ø 9

H7 on the opposite side is precisely positioned in the mounting

position.

The air connection is normally made via the bottom coupling holes

in the floor of the unit.

Alternative connection option:

Two side G1/8" connections which are free when the lower

centering diameter Ø 110 H6 is used. In this case, the bottom

openings must be sealed. To do so, insert the Ø 9 x 1.5 O-rings into

the module and seal the bottom direct connections against the flat

support surface.

Two coupling mechanisms for separate media transfer units are

integrated into the module. They are actuated on the bottom of

the module. O-rings are used in the transfers units for sealing.