Assembly

16

06.00 | NSA plus 120; NSA plus 160 | VERO-S quick-change pallet system | en |

0489070

6.1 General assembly notes

If you wish to install the unit yourself, please request our

drawing.

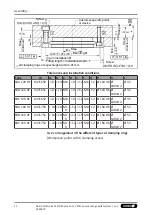

If several clamping units are to be mounted in serial connection,

please make sure that the evenness and deviation in height of the

supporting surfaces from module to module keeps within 0.01 mm

(relating to a depth gauge of 200 mm). The deviation of the

interface position should not exceed ± 0.015 mm.

Due to the redundancy, clamping systems that are lying further

than 160 mm apart from each other or whose positioning

tolerance is not within ± 0.01 mm should use clamping rings with

positioning accuracy in one direction (SRB 120). For clamping

positions which are not used for alignment of the devices or

pallets, clamping rings with centric scope (SRC 120) can be

used

.

NOTE

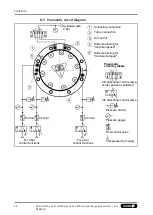

When connecting the quick change pallet system, please make

sure that a complete deaeration of the piston area during the

locking operation is possible through the air ports. Therefore,

valves or stop valves for deaeration should be available. If the

turbo connection will not be used, it must be possible that the

relevant piston side can be deaerated. If the pneumatic port for

turbo effect should not be used, the concerned piston side must

have to possibility to deaerate itself.

When uncoupling the air hoses the corresponding openings have

to be sealed with sealing plugs in order to prevent ingress of dirt

or coolant into the module. If several clamping units are actuated

with common air hoses, the following minimum cross section of

the air feedings have to be respected.

Number of modules

min. internal hose diameter

1

4 mm

2, 3, 4

6 mm

5

8 mm