Screw tightening torques

32

02.00|1416054_ROTA-M2 + 2 |en-US

The calculated RPM n

perm

= 1495 RPM is smaller than the

maximum permissible RPM of the lathe chuck n

max

= 3200 RPM

This calculated RPM may be used.

Accuracy classes

Tolerances for run-out accuracy and axial run-out accuracy

correspond to the Technical Supply Terms for lathe chucks as per

DIN ISO 3442-3.

Permissible imbalance DIN ISO 21940-11

The ROTA-M flex 2+2 in ungreased state without T-nuts and top

jaws corresponds to the balancing quality class 6.3 (according to

DIN ISO 21940-11). Residual imbalance risks may arise due to

insufficient rotation compensation being achieved (see DIN EN

1550 6.2 e). This applies particularly to high speeds, asymmetrical

workpieces or the use of various top jaws, as well as uneven

application of lubricants. In order to prevent damage resulting

from these residual risks, the entire rotor is to be dynamically

balanced in accordance with DIN ISO 21940-11.

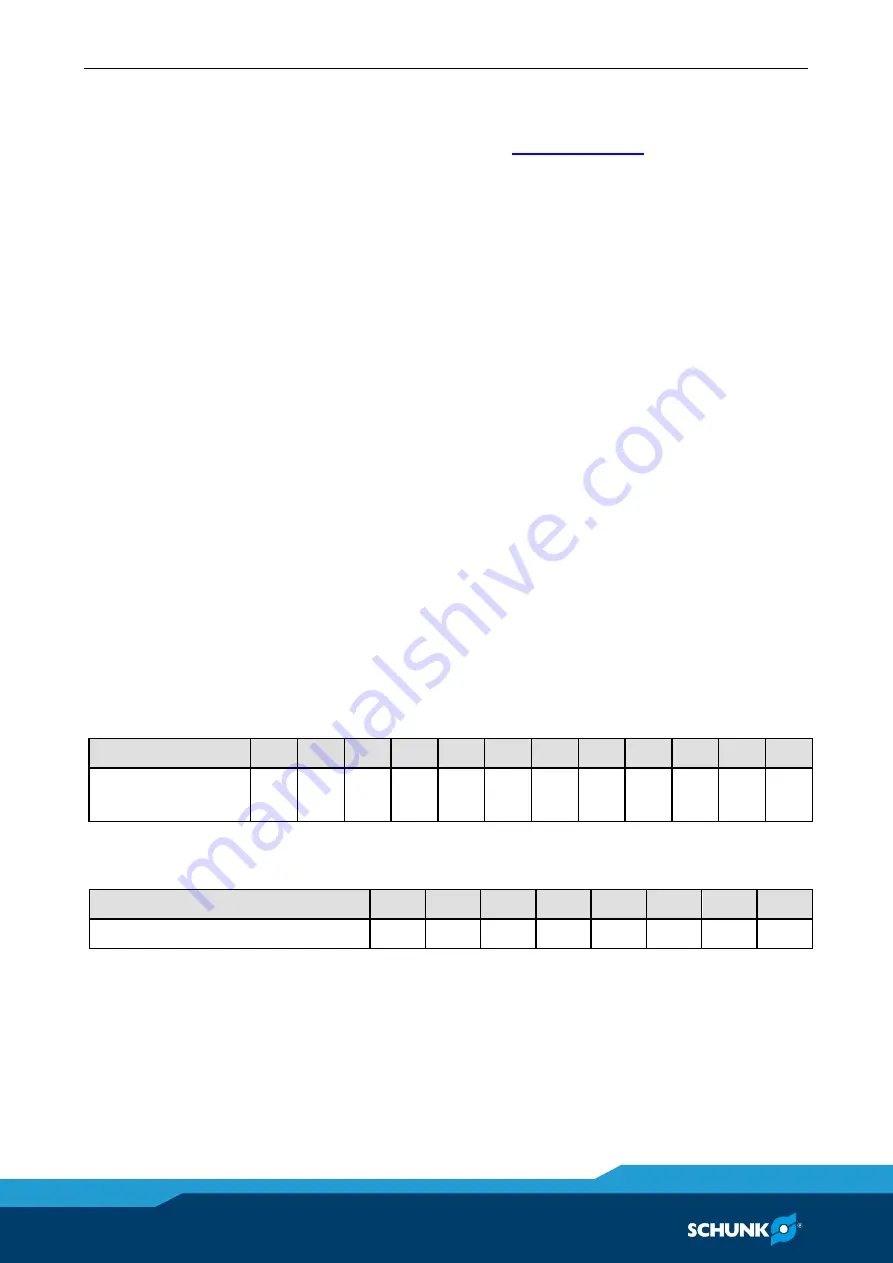

Screw tightening torques

Tightening torques for mounting screws used to set up the lathe

chuck on lathes or other suitable technical equipment and screws

of the lathe chuck itself.

(Screw quality 10.9)

Screw size

M6 M8 M10 M12 M14 M16 M18 M20 M22 M24 M27 M30

Tightening torques

M

A

(Nm)

13

28

50

88

120 160 200 290 400 500 1050 1500

Tightening torques for mounting screws used to attach top jaws

onto the chuck

(screw quality 12.9)

Screw size

M6

M8

M10 M12 M14 M16 M20 M24

Tightening torques M

A

(Nm)

16

30

50

70

130

150

220

450

3.5

3.6

4