Maintenance

34

03.00 | ROTA 2B | Assembly and operating manual | en | 0889059

NOTE

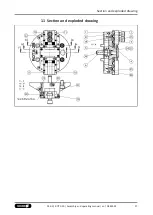

When assembling, ensure that the number of notches on the

base jaw is identical to the numbering on the jaw guide in the

chuck body (item 1).

8. Undo screws (item 19) and pull out second filler (item

8).Remove cylindrical pin (item 28).

9. Remove O-ring (item 35) from filler.

Chuck with optional central oil lubrication:

• The two threaded plugs (item 12) can be unscrewed out of the

chuck body (item 1). Take the two gauge cartridges (item 26)

out of the chuck body.

Clean all parts of dirt and grease and check for damage.Before

mounting, grease well with lubricant LINO MAX.

NOTE

If parts are found to be damaged, they must be replaced by

original SCHUNK replacement parts, or, in the case of standard

parts, by parts with the appropriate DIN code (important too for

screws – quality class).

Mounting of the chuck follows in reverse order.

9.2 Lubrication

To maintain the safe functioning and high quality of the chuck, it

has to be regularly lubricated according to the maintenance

intervals below. (item 23).

Important note

The chuck should always be lubricated in the position in which the

base jaws are radially outermost. (This corresponds to the front

piston position).

For optimum grease distribution, the clamping piston must travel

the entire clamping stroke several times after lubrication.

Operating conditions

Depending on the operating conditions, check the function and

clamping force after a specific period of operation (see

"Maintenance intervals"

). The most accurate way to

measure the clamping force is with a clamping force tester.

Technical condition

When the smallest possible actuating pressure is applied (clamping

cylinder), the base jaws must move evenly. This method only

provides a limited indication and does not replace the

measurement of the clamping force.