EFA stunning device Original operating instructions

EN

Rev.01

– 01.2021

20 of 28

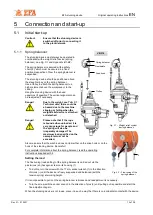

a

c

b

d

Safety bush

Venting slots

8

Maintenance and repair

8.1

Maintenance

Note!

Observe all safety

instructions

.

Danger!

Maintenance work is only allowed to be

carried out by qualified and instructed

personnel.

Danger!

Disconnect the stunning device from the

compressed air network before maintenance

work.

To ensure the longest possible service life and low wear and tear, the

stunning device must be checked and serviced regularly.

Only use genuine spare parts or spare parts recommended by

Schmid

& Wezel GmbH

Maschinenfabrik.

8.1.1

Before and during slaughter

To ensure trouble-free operation, it is essential to use an oil mist

lubricator R 3/8" with filter, regulator and oiler (included in the

compressor) for the compressed air supply.

Only use acid-free brand-name oil (order no. 001365612).

Oiler setting: 1 drop of oil for about 10

– 15 shots.

Regularly check that there is sufficient oil in the reservoir tank.

Drain condensate from the water separator regularly.

8.1.2

After slaughter

After completing the slaughtering, disconnect the device,

see

section 5.1.5

– Uncoupling the stunning device

.

Oil the moving parts, such as:

release valve, safety button and rocker (VB 215 and VB 225) or safety

bush, trigger and rocker (VB 316), and check for freedom of

movement.

VB 316

After the cattle stunner has been checked and cleaned, retighten

the screws daily or every 1000 shots,

see Fig. 8.2

:

a) the screws of the cover (30 Nm),

b) the screws of the hoop (25 Nm),

c) the screws of the handles (30 Nm),

d) the screws of the base plate (30 Nm).

Note!

VB 215

and

VB 225

:

Do not allow water to enter the venting

slots,

see Fig. 8.1

– Maintenance

work

.

Trigger &

rocker

VB 215

and

VB 225

VB 316

Fig. 8.1

– Maintenance work

Safety

button

Trigger &

rocker

Fig. 8.2

– Retightening screws and

oiling parts