3

TFH 232 AS

Operating instructions

Safety foot switches

EN

AS-i Outputs:

DO 0 DO 3:

no Function

AS-i Parameter bits:

P0:

Channel 2 switched;

P1 P3:

no function

Input module address:

0, preset to address 0, can be changed

through AS-interface bus master

or hand-held programming device

LED switching conditions display (internal):

LED yellow:

Channel 1, SaW-Bit 01

LED green-red (AS-i Duo LED):

AS-Interface supply voltage /

AS-Interface communication error /

slave address = 0 or

periphery error detected

LED yellow:

Channel 2, SaW-Bit 23

Only for use in Pollution Degree 2 Environment

For use in NFPA 79 Applications only

Adapters providing ield wiring means are available from

the manufacturer Refer to manufacturer’s information

2.5 Safety classification

Standards:

EN ISO 13849-1, IEC 61508

PL:

up to c

Control category:

up to 1

PFH-value:

≤ 1,14 × 10

-6

/h

up to max 36500 switching cycles/year

PFH-value:

≤ 2,94 × 10

-6

/h

up to max 36500 switching cycles/year

SIL:

up to 1

Service life:

20 years

3. Mounting

3.1 General mounting instructions

The itting may only be carried out by authorised personnel

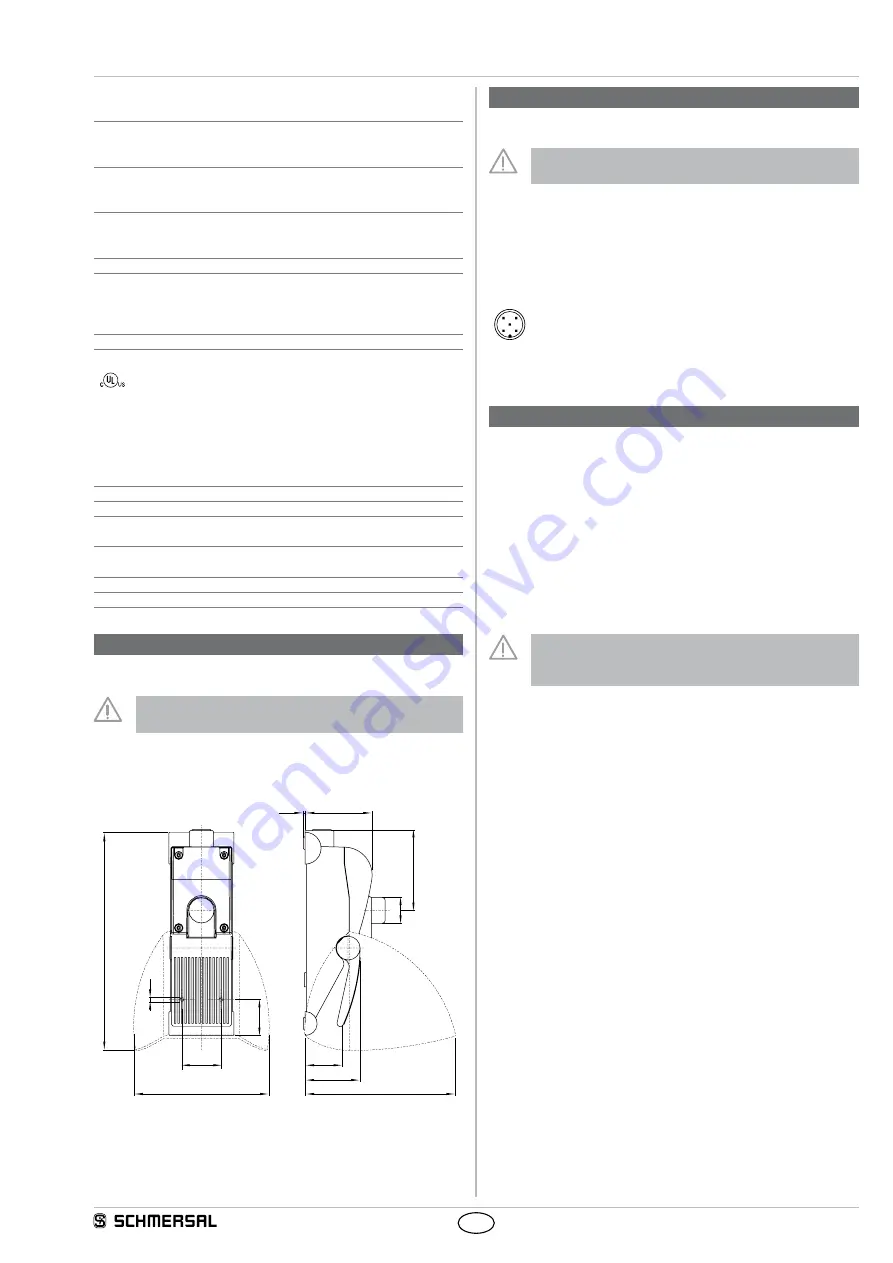

3.2 Dimensions

All measurements in mm

274

84

2,2

189

48

69

170

M6

45

49

100

¤33

4. Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in a de-energised condition

The connection to the AS-Interface system is realised through an M12

connector The connector is A- coded, the wiring configuration is deter-

mined as follows (to EN 50295)

Pin assignment M12 connector

5-pole

3

2

5

1

4

PIN 1: AS-i +

PIN 2: spare

PIN 3: AS-i -

PIN 4: spare

PIN 5: FE (functional earth connection)

5. Functions and configuration

5.1 Programming the slave address

The slave address is programmed through the AS-i connector Any

address from 1 to 31 can be set by means of the AS-i bus master or a

hand-held programming device

5.2 Configuration of the safety monitor

The safety switch can be configured in the ASIMON

configuration software with the following monitoring devices

(refer to ASIMON manual):

Double channel independent

• Optionally with startup test

The configuration of the safety monitor must be tested and

confirmed by a qualified and authorised safety expert/safety

engineer

5.3 Status signal "safety release"

The "safety release" status signal from a Safety at Work slave can be

cyclically queried by the control system through the AS-i master To that

effect, the 4 input bits with the varying SaW code of a Safety at Work

slave are evaluated through an OR operation with 4 inputs in the control

system