4

Operating instructions

Safety light curtain/safety light grid

SLC440AS

SLG440AS

EN

SLC440AS Resolution 30 mm

Protected

height

[mm]

Beams

[lines]

Response

time

[ms]

Response time

Beam coding A

[ms]

Weight

[kg]

170

8

13

18

04

250

12

13

18

05

330

16

13

18

06

410

20

13

18

08

490

24

13

18

09

570

28

13

18

10

650

32

13

18

11

730

36

13

18

12

810

40

13

18

14

890

44

13

18

15

970

48

13

18

16

1050

52

23

30

17

1130

56

23

30

18

1210

60

23

30

20

1290

64

23

30

21

1370

68

23

30

22

1450

72

23

30

23

1530

76

23

30

24

1610

80

23

30

26

1690

84

23

30

27

1770

88

23

30

28

SLG440AS

Beams

[Number]

Beam

distance

[mm]

Response

time

[ms]

Response time

Beam coding A

[ms]

Weight

[kg]

2

500

13

18

090

3

400

13

18

135

4

300

13

18

150

The total reaction time of the safety guard consists of the

reaction times of the BWS, the maximum reaction time

of the AS-i safety system and the reaction time of the

actuators

Reaction time AS-i safety system:

≤ 40 ms

(AS-i slave + AS-i transm AS-i safety monitor)

2.7 Safety classification

Standards:

EN ISO 13849-1, EN 62061

PL:

e

Control Category:

4

PFH value:

≤ 5.17 x 10

-9

/ h

SIL:

suitable for SIL 3 applications

Service life:

20 years

2.8 Functions

The system consists of a receiver and a transmitter For the described

functions, no further switching elements are required The diagnostics

and the function selection are realised by means of the parameter

adapter (KA-0975), refer to chapter "Parameter setting"

The BWS is set to

„Automatic protection mode“

A possible restart interlock must be configured in the

AS-i safety monitor

The SLC has the following features:

• Blanking of fixed protection field areas

• Blanking of fixed protection field areas with movable edge region

• Blanking of movable protection field areas

The SLG has the following features:

• Blanking of movable protection field areas

Systems with alternative beam coding A can be ordered through

the type code (refer to type code).

2.8.1 Fixed blanking SLC440AS

The SLC440AS can blank stationary objects in the protection field

Multiple protection field areas can be blanked If small changes

are made within the fixed blanking area, each time 1 beam can be

additionally blanked to increase the tolerance See chapter Parameter

setting - Fixed blanking with movable edge regions (P 2)

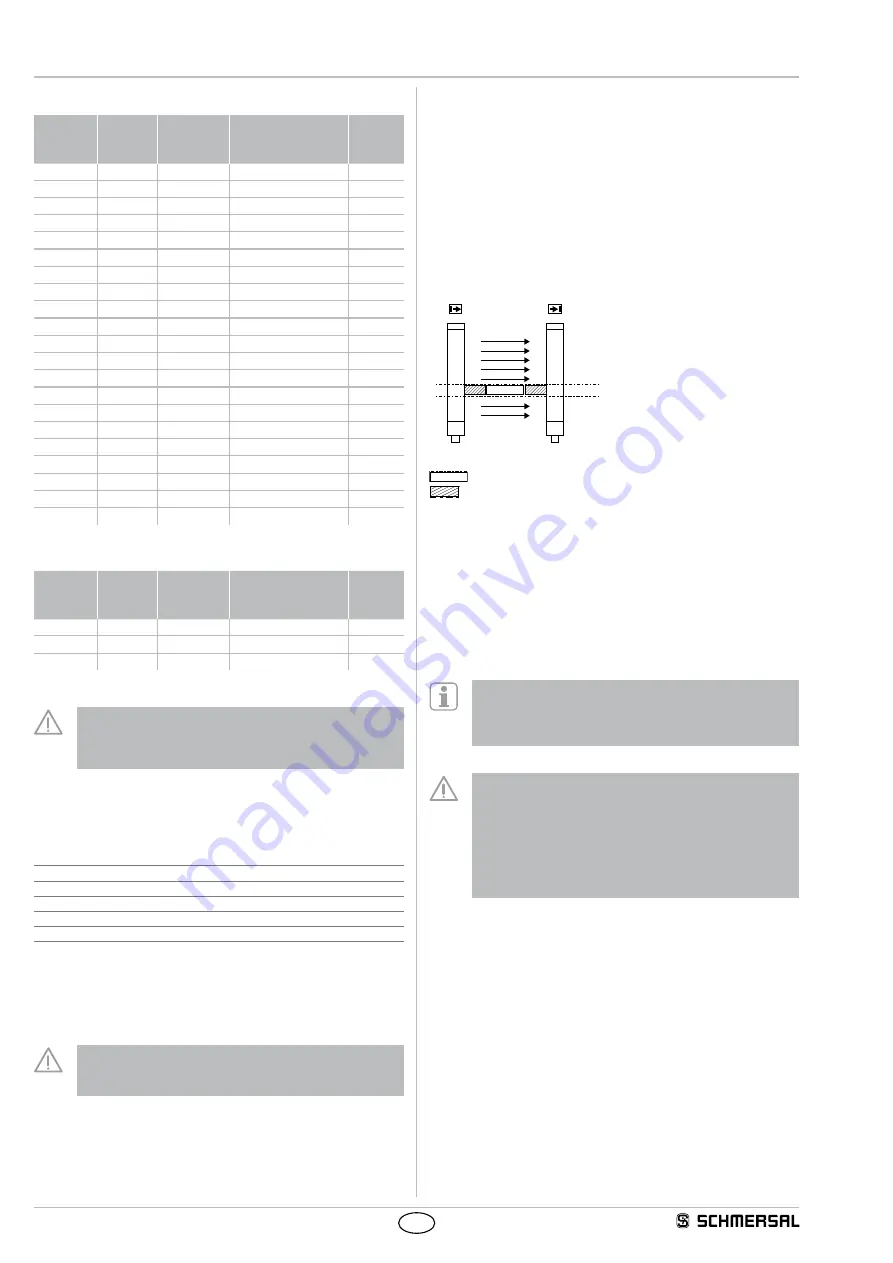

Fixed blanking area

E1

R1

Key

E1

R1

Object in protection field

E1

R1

Mechanical cover

The range of the fixed blanking can be arbitrarily chosen in the

protection field

The first beam line, which realises the optical synchronisation and is

located immediately behind the diagnostic window, cannot be blanked

The area of the fixed blanking must not be modified after the teach-

in process Any change of the area or removal of the object from the

protection field will be detected by the system As a result, the outputs

are disabled (locked) This locking can be neutralised by executing a

new teach-in process in accordance with the actual beam interruptions

The function is activated by means of the parameter setting

(P1) If the function is activated, the LED blanking in the

diagnostic window of the receiver starts flashing

See chapter Parameter settings

•

The remaining lateral areas must be protected against

intrusion by means of mechanical covers

•

The lateral covers must be fixed with the object

•

Partial covers are not authorised

•

After the fixed blanking, the protection field must be tested

by means of the test rod

•

The restart interlock function of the safety light curtain or the

machine must be activated

2.8.2 Fixed blanking with movable edge region SLC440AS

This function can compensate slight position changes of

a

fixed blanked

object with a change of +/- 1 beam This position change corresponds

to an amplitude of /- 10 mm resolution 14 mm and approx

+/- 20 mm resolution 30 mm upwards and downwards in the protection

field