8

Operating instructions

Safety sensor

CSS 34

EN

8. Appendix

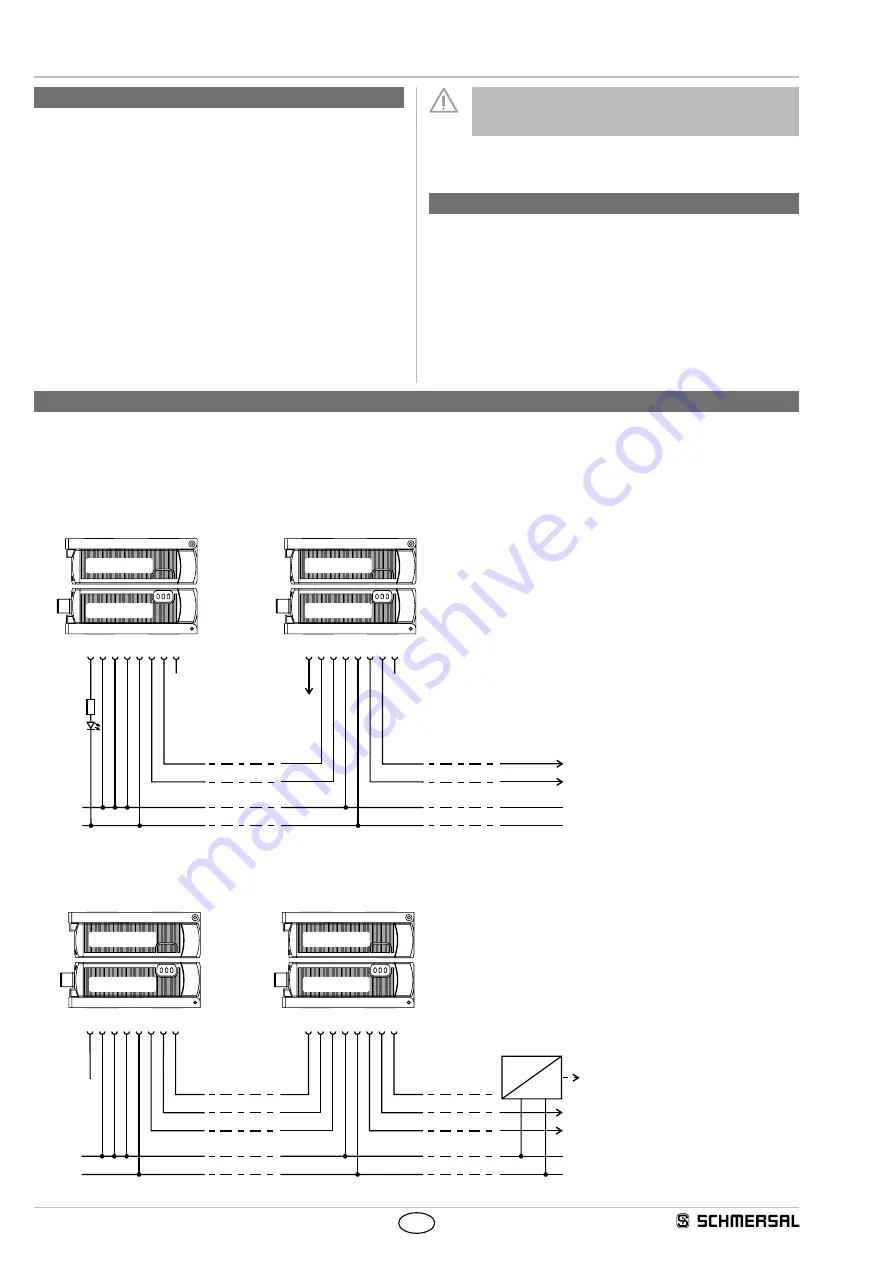

8.1 Wiring examples

The application examples shown are suggestions. They however do not release the user from carefully checking whether the switchgear and its set-

up are suitable for the individual application.

Wiring example 1: Series-wiring of the CSS 34 with conventional diagnostic output

The voltage is supplied to both safety inputs of the last safety sensor of the chain (considered from the safety-

monitoring module). The safety outputs of the first safety sensor are wired to the safety-monitoring module.

X1

Y1

X2

Y2

1

2

3

5

6

8

X1 X2 A1 A2

Y1

Y2

1

2

3

5

6

8

X1

4

Y1

4

Y1

X2

7

Y2

7

Y2

OUT

A1 A2

OUT

SPS/PLC

24 VDC

GND

CST 34-S-1

CSS 34

CST 34-S-1

CSS 34

Safety outputs → Evaluation

Wiring example 2: Series-wiring of the CSS 34 with serial diagnostic function

The safety outputs of the first safety sensor are wired to the safety-monitoring module.

The serial Diagnostic Gateway is connected to the serial diagnostic input of the first safety sensor.

Field bus

1

2

3

5

4

6

8

X1

Y1

X2

SD IN

SD OUT

A1 A2

1

2

3

5

4

6

8

X1

Y1

X2

7

Y2

7

Y2

SD IN

SD OUT

A1 A2

X1

Y1

X2

Y2

SD IN

SD OUT

Y1

Y2

SD IN

24 VDC

GND

CST 34-S-1

CSS 34

CST 34-S-1

CSS 34

Safety outputs → Evaluation

Gateway

6. Set-up and maintenance

6.1 Functional testing

The safety function of the safety components must be tested. The

following conditions must be previously checked and met:

1. Fitting of the sensor and the actuator

2. Fitting and integrity of the power cable

3. The system is free of dirt and soiling (in particular metal chips)

6.2 Maintenance

In the case of correct installation and adequate use, the safety sensor

features maintenance-free functionality.

A regular visual inspection and functional test, including the following

steps, is recommended:

• Check the fitting of the safety sensor and the actuator

• Remove possible metal chips

• Check the cable for damage.

Measures must be taken to protect against manipulation or

against the bypassing of safety device, for example, using an

extra actuator.

Damaged or defective components must be replaced.

7. Disassembly and disposal

7.1 Disassembly

The safety switchgear must be disassembled in a de-energised

condition only.

7.2 Disposal

The safety switchgear must be disposed of in an appropriate

manner in accordance with the national prescriptions and legislations.