8

Operating instructions

Solenoid interlock

AZM 200

EN

9. Appendix

9.1 Wiring examples

The application examples shown are suggestions. They however do not release the user from carefully checking whether the switchgear and its

set-up are suitable for the individual application.

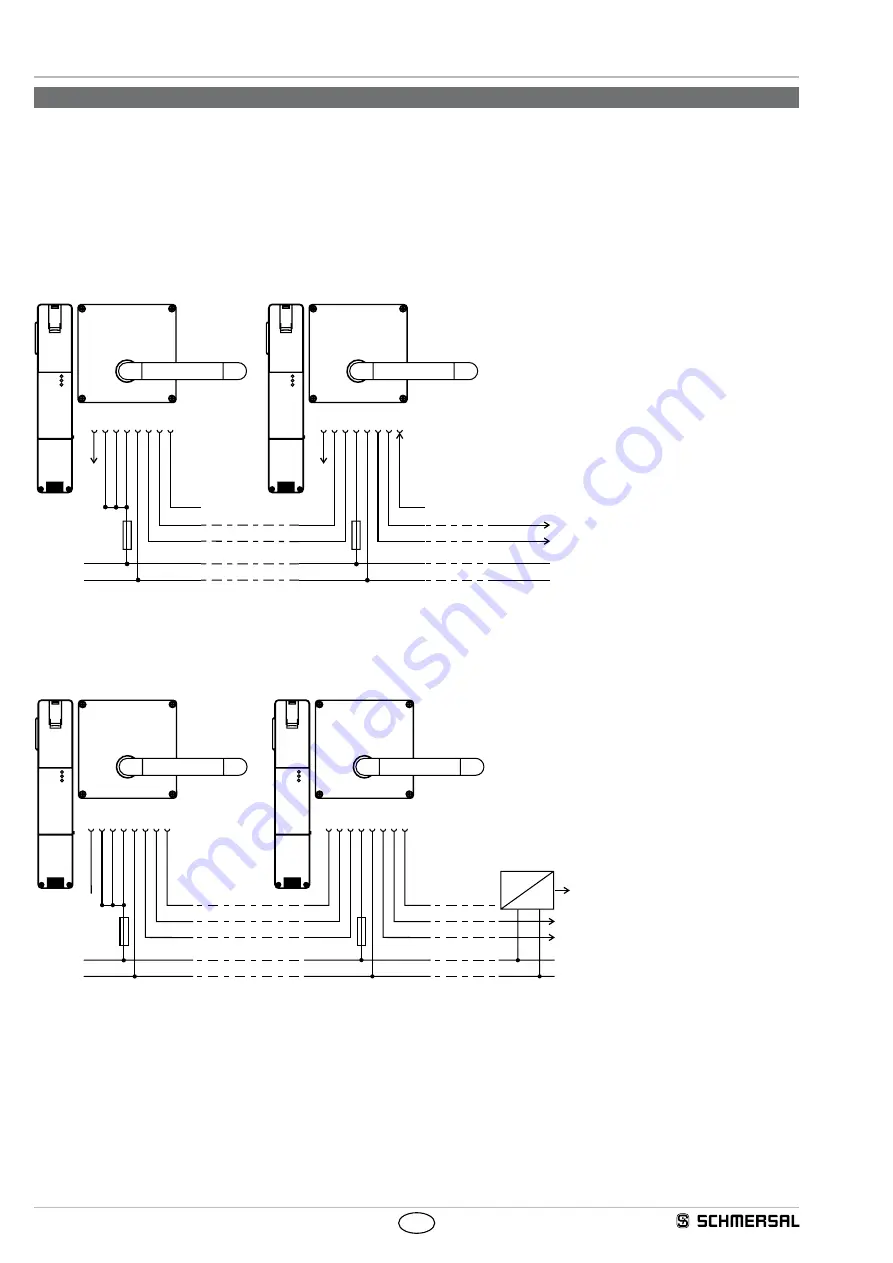

Wiring example 1: Series-wiring of the AZM 200 with conventional diagnostic output

The series-wiring of multiple AZM 200 solenoid interlocks is realised by wiring in the control cabinet or in on-site junction boxes.

In the example, 2 AZM 200 solenoid interlocks (max. 31 components) are wired in series. The diagnostic output ("OUT") and the magnet control

("IN") are separately wired to a conventional PLC for evaluation or control. The maximum cable length of the safety circuits must not exceed 200 m.

In the series-wiring, the 24V-X1-X2 bridge must be removed from all components up to the last component.

The voltage is supplied at both safety inputs of the terminal safety component of the chain (considered from the safety-monitoring module).

The safety outputs of the first safety component are wired to the safety-monitoring module.

X1

Y1

X2

Y2

1

2

3

5

6

8

X1 X2 24V GND

Y1

Y2

1

2

3

5

6

8

X1

4

Y1

4

Y1

X2

7

Y2

7

Y2

OUT

24V GND

OUT

SPS/PLC

IN

SPS/PLC

SPS/PLC

IN

24 VDC

GND

SPS/PLC

n-participants max. 31 components in series

Safety outputs

evaluation

Wiring example 2: Series-wiring of the AZM 200 with serial diagnostic function

The safety outputs of the first safety component are wired to the safety-monitoring module. The serial Diagnostic Gateway is connected to the serial

diagnostic input of the first safety component.

n-participants max. 31 components in series

Safety outputs

evaluation

Field bus

24 VDC

GND

1

2

3

5

4

6

8

X1

Y1

X2

SD IN

SD OUT

1

2

3

5

4

6

8

X1

Y1

X2

7

Y2

7

Y2

SD IN

SD OUT

X1

Y1

X2

Y2

SD IN

SD OUT

Y1

Y2

SD IN

24V GND

24V GND