4

Operating instructions

Safety switch with interlocking function

AZM 200 D

EN

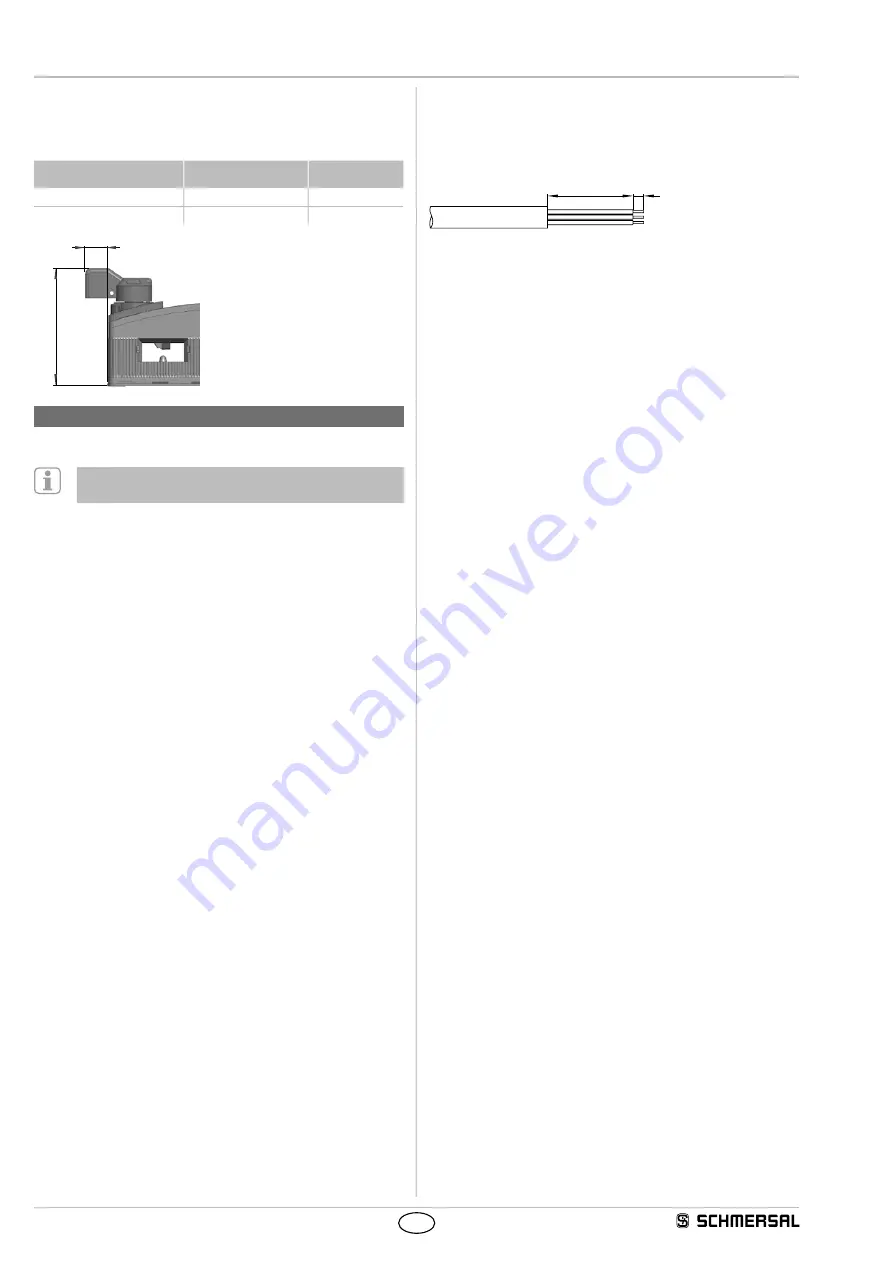

3.3 Retrofit kit for Emergency release/Emergency exit

The retrofit kit is used for subsequent functional expansion of the safety

switch.

Designation

Ordering code

Emergency release

RF-AZM200-N

103003543

Emergency exit

RF-AZM200-T

103004966

71

16

4. Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in a de-energised condition.

The power supply of the safety switch must provide protection against

permanent overvoltage. To that effect, stabilised PELV supply units

must be used. The safety outputs can be directly integrated in the

safety circuit of the control system. For applications up to PL e / control

category 4 to ISO 13849-1, the safety outputs Y1 and Y2 of the safety

switch or safety switches must be connected to a safety-monitoring

module of the same control category (refer to wiring example).

The antivalent switching safety outputs Y3 and Y4 are suitable for

requirements up to PL d / control category 3. To that effect, the outputs

must be connected to a safety-monitoring module meeting at least the

requirements of PL d / control category 3 to ISO 13849-1. The outputs

cannot be wired in series.

Inductive loads (e.g. contactors, relays, etc.) are to be provided with

suitable interference suppression circuitry.

Requirements for the connected safety-monitoring module:

• Dual-channel safety input, suitable for 2 or 4 p-type semi-conductor

outputs

Safety outputs Y1, Y2

The safety-monitoring module must tolerate internal functional with

cyclic switch-off of the safety outputs Y1 and Y2 for max. 2 ms (typically

< 1 ms). The switch-off stage of the test cycle is temporarily reduced

by an active ohmic discharge of the cable. The safety-monitoring

module does not need to have a cross-wire short monitoring function, if

necessary, the cross-wire short monitoring function must be disabled.

Safety outputs Y3 and Y4

The safety outputs Y3 and Y4 are antivalent switching outputs.

A short concordance (< 50 ms) must be accepted, as the AZM 200 D

might present small switching delays.

Cable

If the cable input is realised through a metric M20 cable gland, this

gland must be dimensioned by the user so as to fit the cable used.

A cable gland with strain relief and suitable IP protection class must

be used.

40

5

The maximum cable length is 200 m (for ST2 M12 connectors approx.

20 m depending on the cable section used for an operating current

of 0.5 A). The maximum cable section is 1.5 mm², incl. conductuor

ferrules. Prior to the connection, the cable must be stripped by

40+5 mm and insulated by 5 mm.