390G+ INSTALLATION

INSTRUCTIONS

FORM 39080 REV. E

1

1/2010

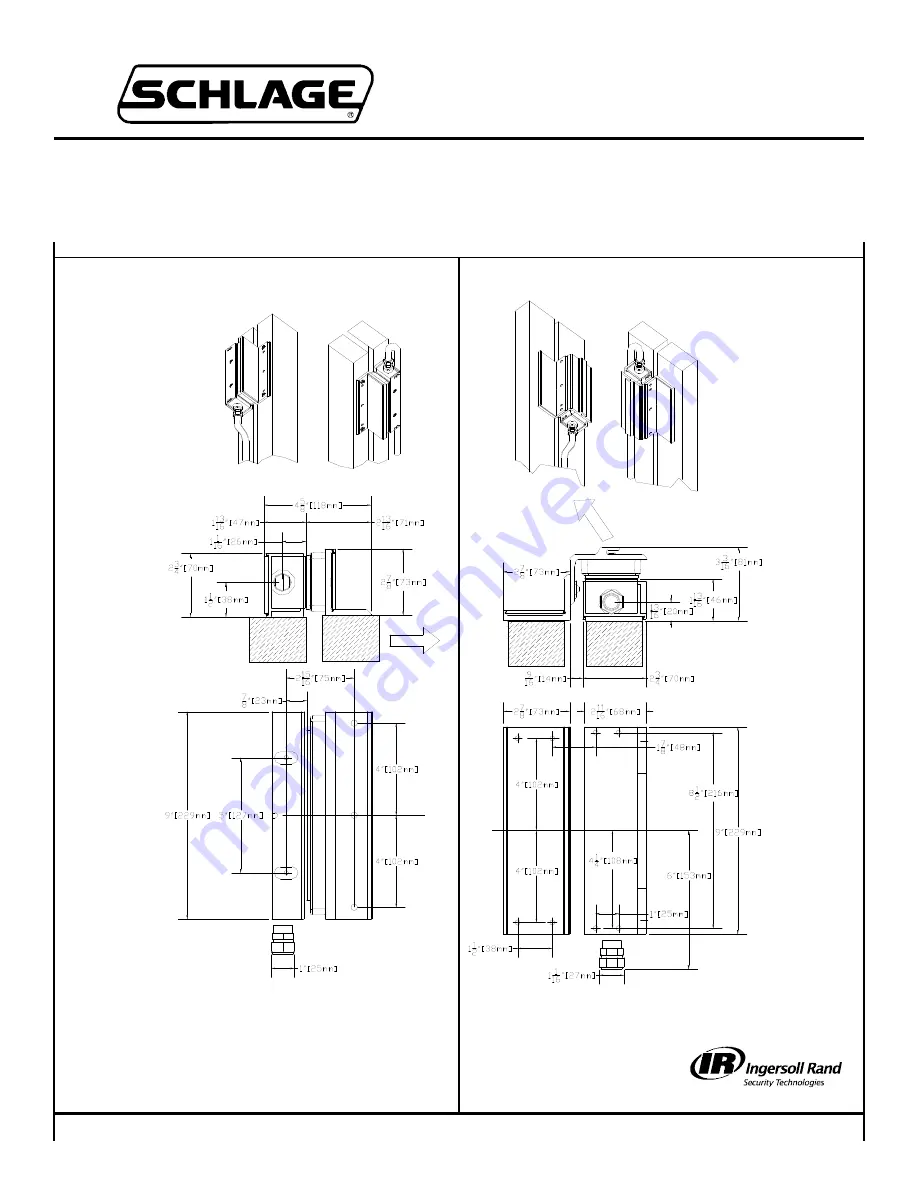

SLIDING GATE APPLICATION TEMPLATE:

SWINGING GATE APPLICATION TEMPLATE:

INSTALLATION CONSIDERATIONS:

The 390G+ is an electromagnetic lock designed for use on exterior gate applications, though it can be used indoors under circumstances where conduit-enclosed wiring is

desirable or unavoidable. These instructions cover two basic mounting situations: swinging and sliding. Other mounting situations may be encountered which may necessi-

tate fabrication of custom brackets or reinforcements to accommodate the lock. Wiring should be protected by conduit. Wire leads provided are 24 inches long and provi-

sions should be made for connections within that distance. You must determine which type of mounting screws provided will best suit your installation. For light-gauge metal

frames, self tapping screws may be used. If the frame is heavy gauge metal, machine screws may be required to adapt the lock to a particular post or frame. Armature

mounting hardware is provided for direct mounting. The sex nut (provided) can be used instead of the TJ brackets, if mounting the armature on a standard, 1-3/4” door.

Other sex nuts, of different lengths, are available from Locknetics distributors. Refer to the last page for parts list with pictures.

Schlage Lock Company

575 Birch Street

Forestville, CT 06010

technical support: 866-322-1237

email: [email protected]

web: www.irsupport.net