Installation, Mounting and Maintenance DISA-H

Z11/31 - 8

Construction subject to change.

No return possible!

Version:

Checks

Prior to commissioning, the following items must be checked or

guaranteed:

During commissioning itself, the following items must be guar-

anteed:

Maintenance

For reasons of safety, the power supply and hydraulic circuit

must be disconnected prior to any maintenance activity.

If the unit was operated in heating mode, you have to wait until

the register has cooled down.

Air ducts and plenum box/grilles

Clean them by blowing compressed air through them or using

non-aggressive cleaners.

Registers

To guarantee the technical characteristics of the device, the reg-

isters and heat exchangers must be kept in good clean condition.

To ensure this, the following maintenance activities must be car-

ried out:

If condensates are detected, interrupt the hydraulic circuit and

find the possible cause of the problem.

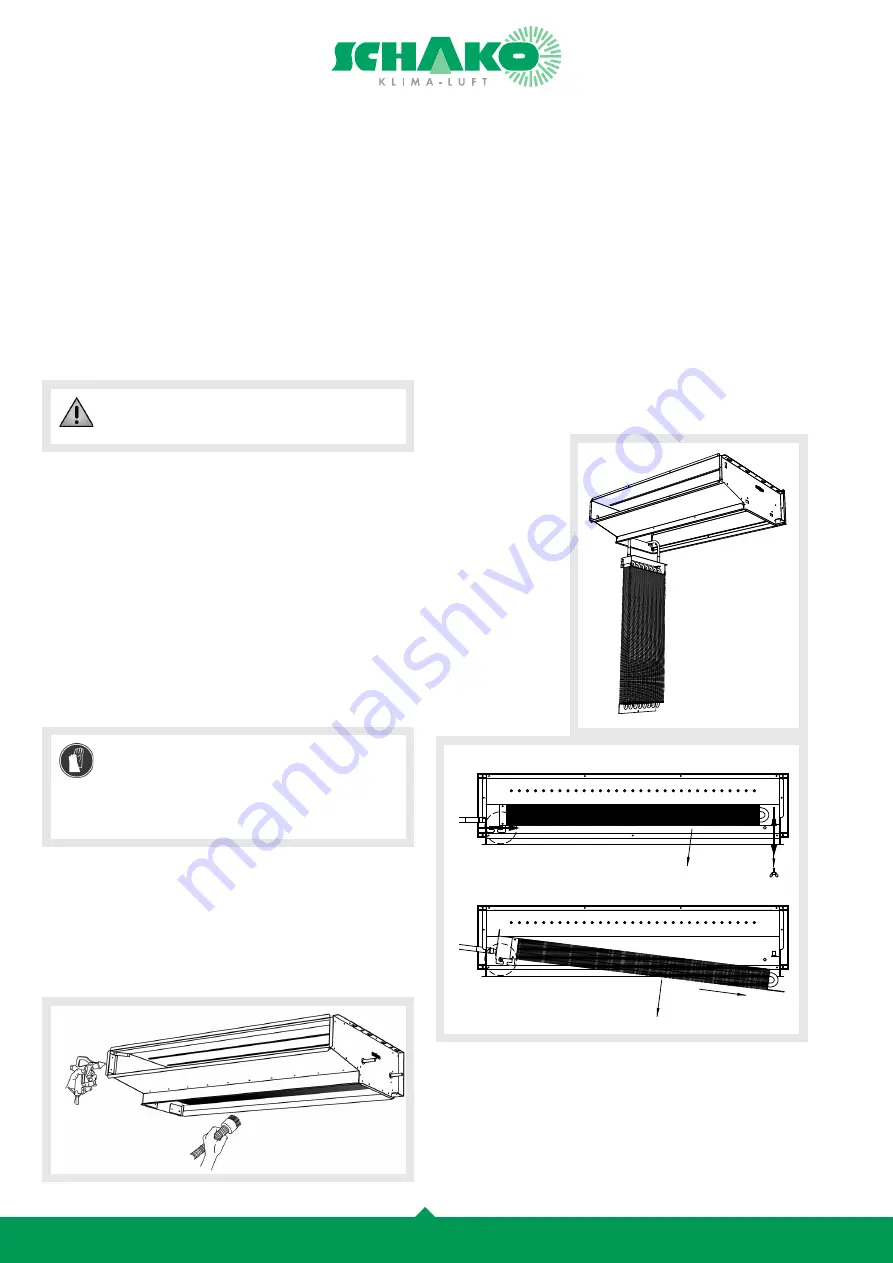

To facilitate the

maintenance activi-

ties, the register can

be completely re-

moved. Please follow

the sequence shown

in the following fig-

ures.

To allow the register

to be folded down, it

must be connected

to the hydraulic cir-

cuit with flexible hos-

es of sufficient

length.

- Hydraulic connections were tightened properly and exhib-

it no leaks.

- Connecting and fastening elements have been sufficiently

tightened.

- Adequate access for carrying out the maintenance activi-

ties has been provided.

- Use the on-site ventilation devices to ensure that no air re-

mains in the register and the water circuit.

- The connecting and fastening elements have been suffi-

ciently tightened.

- In heating mode, the temperature of the discharged sup-

ply air is not above 40°C.

After these items have been taken care of, the cor-

rect fastening of the device must be checked.

When performing maintenance activities, it is rec-

ommended wearing personal protective equip-

ment, in order to avoid cuts and other injuries

produced by sharp and pointed parts.

- If the register is soiled, clean it by spraying it with water

or compressed air or by evacuation.

- Please do not use any scouring agents for cleaning since

these materials may impair or damage the DISA-W (gal-

vanised steel, aluminium and copper) and the surface

coatings (paints and anodised surfaces).

- If there are larger differences in distance between the ribs,

they must be "combed".

- Ventilate the hydraulic circuits of the register. In doing so,

watch out for possible leaks of the hydraulic system.

1

2

3

4

2