Installation, Mounting and Maintenance DISA-360

Construction subject to change.

No return possible!

Version:

When charging the register, make sure by means of on-site ven-

tilation devices that no air remains in the hydraulic circuit.

If the unit is to be installed at a location having temperatures be-

low zero degrees, glycol must be admixed to the coolant in a

suitable ratio, to ensure that the freezing point of this liquid al-

ways stays below the minimum temperature of the operating

site. Please note that the use of an antifreeze necessarily results

in a loss in performance of the register.

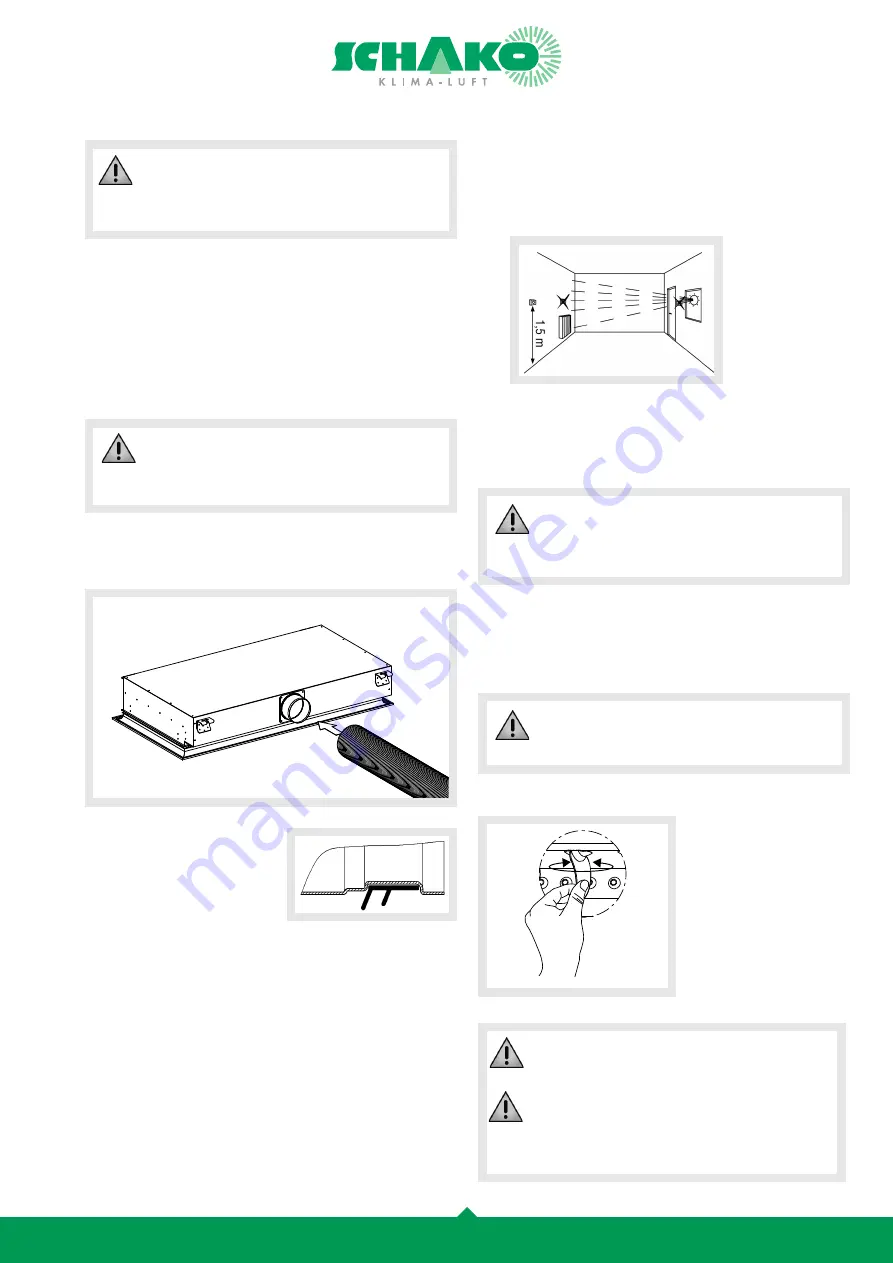

Connecting the air ducts

The air ducts are attached by using pipe clamps, fixing lugs or

the like.

Optionally, a rubber lip seal can

be installed on the connection

pipe, to ensure tightness be-

tween the device and the pipes.

Mounting accessories

Valves and actuators

Valves and actuators shall not be installed ex works. During in-

stallation the manufacturer's specifications must be observed.

Temperature controls

The temperature controls are mounted in accordance with the

selected model. This is why the instructions enclosed with each

model must be followed. However, in order to achieve optimum

measurement by the sensors, the following basic information

should be observed:

Condensate monitor

The installation of a condensate monitor depends on the select-

ed model. Please follow the instructions enclosed with each

model.

Adjustment of the air deflection blades

To regulate the air flow, ro-

tate the air deflection blades

manually.

With blockwise adjustable

blades, 5 blades can be ad-

justed simultaneously.

In order to achieve a uniform cooling capacity, the

ceiling induction diffusers type DISA-360 should be

connected to the cold water distribution system in

parallel.

The ceiling induction diffusers type DISA-360 are

induction devices for "dry cooling". To avoid con-

densates, the water inlet temperature should be

higher than the dew point.

- Do not mount the temperature control close to or above a

heat source (direct sunlight, lamps, television sets, radia-

tors, etc.), in places with draught air or directly opposite

to an air diffuser grille.

- Temperature controls must be mounted at least 1.5 me-

tres above the floor.

- Mounting temperature controls on walls toward the out-

doors should be avoided.

Before drilling, make sure that no electric cables

are present in the wall where the temperature con-

trol is to be mounted.

is attached no electric cables are present.

Faulty mounting of the sub-assemblies and of the

accessories of the unit can result in a substantial

power loss of the unit.

The adjusting angle of the air deflection blades

must not be more than ± 45°, in order to guarantee

its function.

At an adjusting angle of the air deflection blades

outside the straight air throw of up to 45°, the cool-

ing capacity of the heat exchanger is reduced by up

to 5%, and the horizontal throw is reduced.