33

SCAIME Manual : NU-eNod4C-E-0418-196712-F.docx

eNod4-C

automatically calculates a result corresponding to the object weight. This result value may be weighted by a

coefficient.

A value representative of the quality of the result is also determined. This value is the standard deviation of

measurements acquired during the measuring time; more this value is low, the better the checkweigher result.

If target and tolerances (+-) have been defined, the checkweigher result is checked and logical outputs can be activated

(see logical outputs chapter).

Each cycle is counted and the following statistical data are updated for each new complete cycle:

•

results average

•

running total (results sum)

•

number of cycles

•

standard deviation

•

number of out of tolerance results

Statistics can also be calculated only on “within tolerances” results.

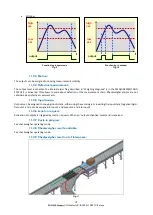

eNodView

can be used to determine stabilization and measurement times so as to optimize parameters. (See

eNodView

user’s instructions documentation).

9.2

Providing results

- The assigned output, if configured, can switch as soon as a result is available. The result can therefore be read. A new

cycle start cancels the previous result (value is ‘FF FF FF FF’).

-

It is also possible to cancel the result (set to ‘FF FF FF FF)’ before nex t cycle start using an input assigned to ‘clear’ o

r

using the clear command. Warning: In this case, statistic values are cancelled (number of cycles, standard deviation,

result sum and mean….).

Note

: In SCMBUS Protocol:

•

In ‘checkweigher automatic transmission mode’ the result is send on serial bus at the end of the cyle.

Following a transmission, results is set to °???????.

•

In ‘checkweigher transmission on request mode’, any output assigned to this function switch as soon as result

is available. When read, the result is set to °????????, as when a new cycle starts.

9.3

Management of Set-points:

Outputs may be assigned to the set-point function, especially for the monitoring of exceedance of the checkweigher

running total value (cumulated weight) or the number of results out of tolerances.

9.4

Dynamic zero

If an input assigned to the

‘dynamic zero’

function is activated or if a

‘dynamic zero’

command is received,

e

Nod4-

C

calculates the measurement average value during a configurable time. This value becomes effective if it is within a ±

10% range of the specified maximum capacity. Stability is not required.

9.5

Checkweigher zero automatic correction

eNod4-C

also provides an automatic zero tracking for dynamic applications. It allows following the evolution of the zero

in checkweigher functioning mode, for example on a conveyor belt on which there is some product accumulation.

When used in legal metrology, this device is imperatively activated with criteria that are limited (see § 'legal

metrology').

This function is efficient only when the measured signal is filtered enough with few noise and oscillations.

When this function is enabled, an average value is calculated if comprised within a configurable interval around the

calibration zero. Some other criteria are also taken in account:

•

A minimum of 75% ratio between accepted measurements and total measurements received during

checkweigher dynamic correction time is considered.

•

A minimum of 10 measurements accepted during correction time is necessary.

In legal for trade mode:

•

A maximum correction range of ±5 d is admitted.

•

Time during measurement average is calculated is at least 1 second.

To use checkweigher zero automatic correction it is recommended:

•

Use it only if belt conveyor is in use.

•

Zero dynamic time should be higher to checkweigher measuring time.

•

Zero dynamic time should be lower than free time between two arriving loads.

•

Zero dynamic interval should be lower than checkweigher trigger level.

•

Zero dynamic interval should be in connection with mechanical vibrations, it should be lower than 10d.