5-24

MAINTENANCE

SY60C Excavator OMM

Climate Control System

NOTE:

When the air conditioning will not be used for an extended period of time, it should be operated for 3 to 5 minutes

each month to lubricate compressor components and air conditioning system seals.

Service Intervals

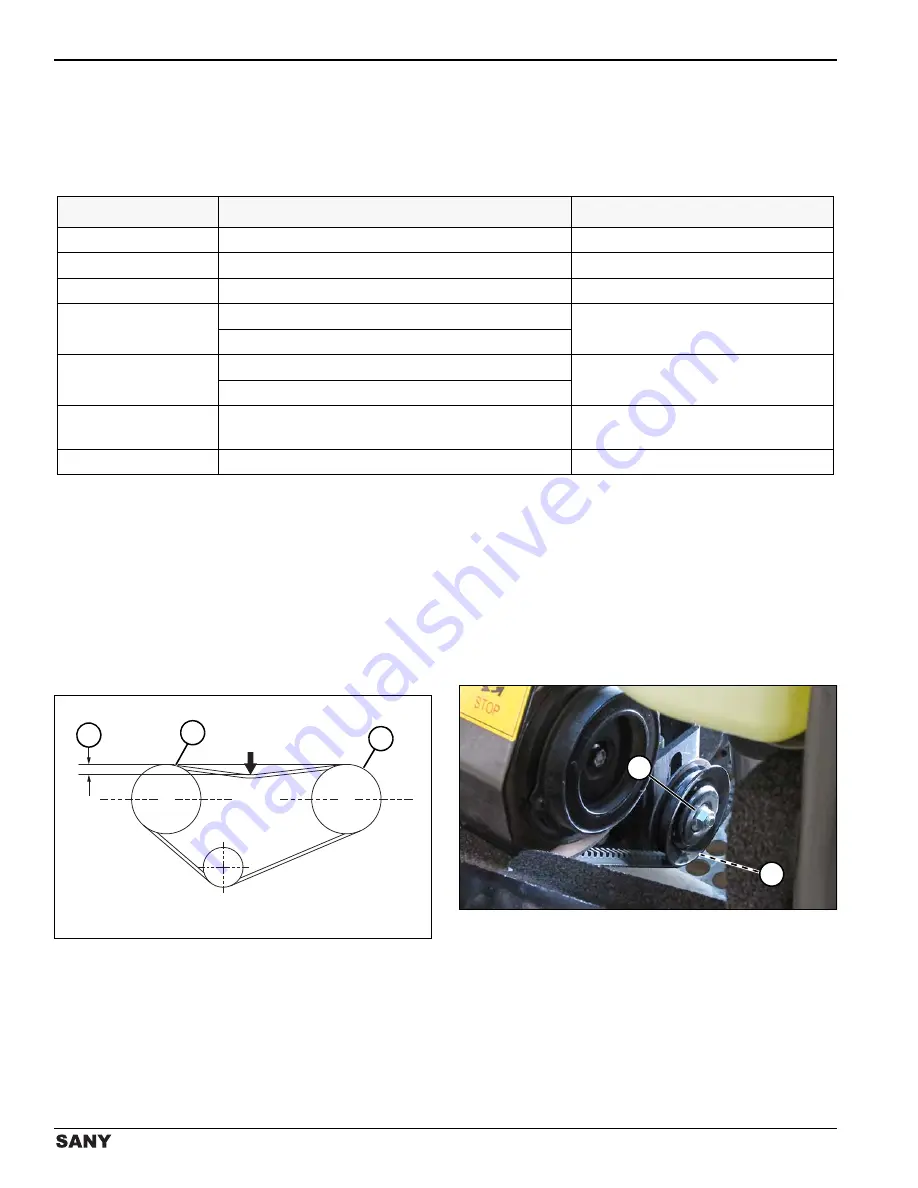

Check and Adjust the Air Conditioner

Compressor Belt Tension

Two Methods of Checking Belt Tension

Prepare the machine for service. See “Maintenance

Safety” on page 2-5.

• Use a tensioning gauge to check the tension of the

compressor belt. A new belt should be tightened to

143 lb. (637 N), and a used belt should be tightened to

99 lb. (441 N).

0002961

Figure 5-29

• Press down on the belt halfway between the drive belt

pulley (3) and the compressor belt pulley (2). The belt

must deflect (1) 0.20 in.–0.31 in. (5 mm–8 mm).

Adjust the Air Conditioner Compressor Belt Tension

NOTICE!

Check the pulleys and V-belt for damage and

wear. Make sure that the V-belt does not rub

against the bottom groove of the pulleys.

A newly installed V-belt must be readjusted after

operating the machine for 1 hour.

0002958

Figure 5-30

1.

Prepare the machine for service. See “Maintenance

Safety” on page 2-5.

2.

Loosen the belt adjustment pulley locknut (1) and

turn the tension adjuster (2) to achieve the correct

belt tension.

3.

Tighten the belt adjustment pulley locknut.

Item

Description

Service Interval

Refrigerant (R134a)

Check for leaks in lines, fittings, and components.

Daily

Condenser

Check if condenser fins are plugged.

When required

Compressor

Check the compressor function and for leaks.

Every 4000 service hours

V-belt

Check tension.

Every 250 service hours

Check for damage, wear, and deterioration.

Blower speed

adjustment dial

Check fan motor and fan operation.

Daily

Check speed adjustment function.

Temperature

adjustment dial

Check for normal operation.

Daily

Fasteners

Check for missing or loose fasteners.

Every 6 months

1

2

3

2

1