MAINTENANCE

5-39

SY60C Excavator OMM

Lubrication

Lubrication Points

0002197

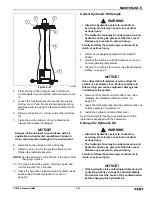

Figure 5-4

See “Lubrication and Maintenance Charts” on page 5-11

for additional information.

NOTE:

A new machine must be greased every 8 hours

within the initial 50 service hours.

If the lubricated location produces abnormal noise,

additional lubrication is required besides regular

maintenance.

More frequent lubrication is required when the machine is

operated with heavy optional equipment (e.g., a hydraulic

breaker).

After operating in water, grease the machine to expel any

water from the lubrication points.

1.

Prepare the machine for service. See “Maintenance

Safety” on page 2-5.

2.

Using a grease gun, pump grease into the grease

fittings.

3.

Clean off all excess grease.

Arm Cylinder Rod End Pin

0003021

Figure 5-5

1.

Remove the grease fitting cap (1) from the arm

cylinder rod end pin grease fitting (2).

1

Arm cylinder rod end pin (page 5-39)

9

Dozer blade linkage pins (page 5-41)

2

Boom-arm connecting pin (page 5-40)

10 Dozer blade cylinder end pins (page 5-42)

3

Arm cylinder base end pin (page 5-40)

11 Boom swing cylinder rod end pin (page 5-42)

4

Boom pin (page 5-40)

12 Boom cylinder base end pin (page 5-42)

5

Boom swing cylinder base end pin (page 5-40)

13 Boom cylinder rod end pin (page 5-42)

6

Swing gear (page 5-41)

14 Bucket linkage pins (page 5-43)

7

Swing bearing (page 5-41)

15 Bucket cylinder rod end pin (page 5-43)

8

Boom swing pin (page 5-41)

16 Bucket cylinder base end pin (page 5-43)

1

2

3

16

14

15

13

4

12

7

5

14

10

9

8

11

6

1

2