5-36

MAINTENANCE

SY60C Excavator OMM

Decrease the Track Tension

NOTICE!

Remove gravel or mud buildup between the

sprocket and the track before reducing track

tension.

NOTICE!

Dispose of used grease in accordance with all

applicable environmental regulations. Failure to

do so could result in damage to the environment.

1.

Slowly open the grease valve (2) 1 to 1-1/2 turns

while observing idler movement. Grease should

come out from behind the grease valve.

NOTE:

If grease does not come out, slowly rotate the

track in both directions. When grease begins to

flow, stop and continue the adjustment.

2.

When the track sag is within specification, tighten the

grease valve to 44 lb-ft–59 lb-ft (60 N•m–80 N•m).

3.

Rotate the track one full revolution. Check track

tension to confirm adjustment.

4.

Position the adjuster cover and tighten the fasteners.

Check and Add Final Drive Oil

CAUTION

• Allow the final drive to cool before servicing. Hot

oil may cause burns or other serious injury.

• Wear safety goggles, gloves, and other personal

protective equipment (PPE) to prevent serious

injury.

• The final drive oil may be under pressure.

Remove the plugs slowly to prevent injury.

Failure to follow these precautions could result in

injury.

0003040

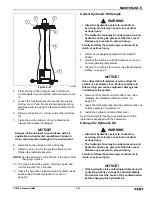

Figure 5-53

1.

Park the machine to position the drain plug (3) at the

bottom of one of the final drives.

2.

Prepare the machine for service. See “Maintenance

Safety” on page 2-5.

3.

Wait 10 minutes for the gear oil to cool.

4.

Place a suitable container under the final drive to

catch any oil that may leak out.

5.

Slowly loosen the oil level plug (2) to relieve any

internal pressure.

6.

The oil should be at or near the lower edge of the oil

level plug opening.

7.

If necessary, remove the fill plug (1) and add oil.

8.

Install the oil level and fill plugs and tighten to

12.5 lb-ft (17 N•m).

9.

Repeat this procedure on the other final drive.

2

3

1