MAINTENANCE

5-11

SY60C Excavator OMM

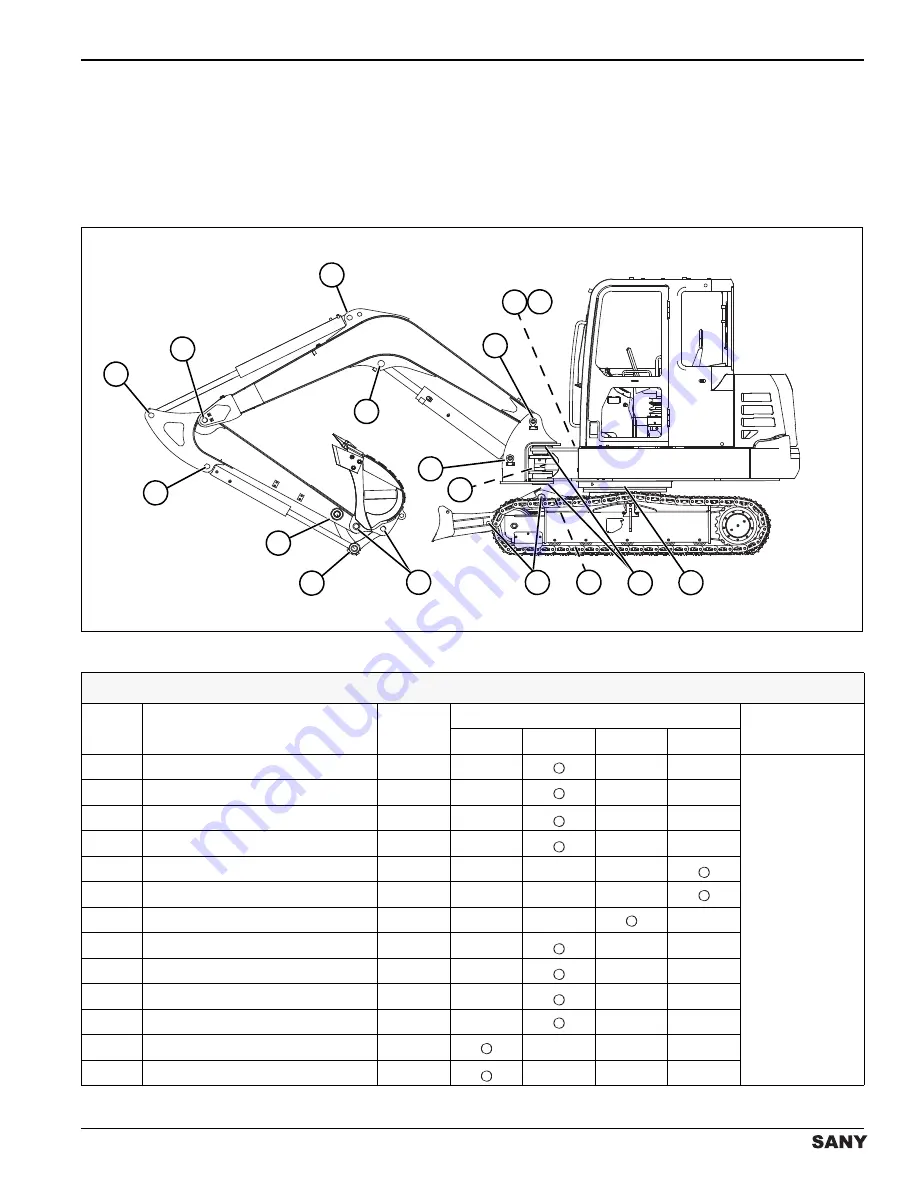

Lubrication and Maintenance Charts

Lubricants are used to minimize wear between moving

parts. Insufficient lubrication will lead to excessive wear

and damage to components. Engine oil is critical for

engine operation. Never use lubricants that are not

SANY-approved.

Clean grease fittings before applying grease. Use a

grease gun to pump grease into the fitting until old

grease begins to escape. Clean off any grease that has

escaped.

Shown below are the lubrication points that must be

maintained according to the lubrication chart. See

“Lubrication Points” on page 5-39.

0002197

Figure 5-1

Lubrication Chart

Item

Maintenance Items

Qty. of

Fittings

Lubrication Interval

Lubricant

Daily

100 hr.

250 hr.

500 hr.

1

Arm cylinder pins

2

Grease

2

Boom-arm connecting pin

1

3

Boom pin

1

4

Boom swing cylinder base end

1

5

Swing gear

1

6

Swing bearing

2

7

Boom swing pin

2

8

Dozer blade linkage pins

2

9

Dozer blade cylinder pins

2

10

Boom swing cylinder rod end

1

11

Boom cylinder pins

2

12

Bucket linkage pins

3

13

Bucket cylinder pins

4

1

2

1

13

12

13

11

3

11

6

4

12

9

8

7

10

5