5-56

MAINTENANCE

SY500H Excavator OMM

0004725

Figure 5-120

3. Remove two fasteners (2) and remove the

inspection/fill hole cover (3).

4. Check the grease color.

NOTE:

Grease with a milk-white color indicates that the

grease is contaminated and must be replaced.

5. Check the grease level by inserting a ruler into the

grease through the inspection/filler hole.

NOTE:

The minimum grease level is 19 mm (0.75 in.).

6. Add grease through the inspection/filler hole as

needed.

7. Install the cover.

Bucket

Replace the Bucket

CAUTION

Driving a pin with a hammer can cause metal

pieces to fly off, leading to severe injuries. Wear

goggles, a hard hat, protective gloves, and other

personal protective equipment (PPE) during these

operations.

Make sure the surrounding area is clear of all

personnel when removing any of the pins. The

pins could fly out and cause personal injury.

Do not stand behind the bucket when removing

pins. Keep hands and feet clear of the underside

of the bucket during removal to avoid injury.

To avoid injury, do not use hands or fingers to aid

in bore alignment.

1. Prepare the machine for service. See “Maintenance

Figure 5-121

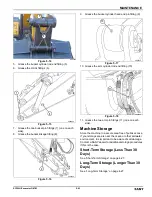

2. Lower the bucket (1) to where it just touches the

ground and block the bucket to prevent movement.

NOTE:

If an excessive downward force is applied,

resistance on the pin could increase, causing

difficulty during removal.

3. Remove the fasteners from the plate retaining the

arm pin (2) and link pin (3).

4. Remove the arm pin and link pin, and remove the

bucket.

Figure 5-122

NOTE:

Make sure to apply grease to the arm and link pins

before installing them.

NOTE:

Make sure the pins are free of mud or sand during

installation. Both ends of the bushing are

equipped with dust seals. Be careful not to

damage them.

3

2

0000819

3

2

1

0000820

4

5

6

7

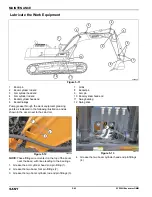

Summary of Contents for SY500H

Page 2: ...Page Intentionally Blank ...

Page 14: ...5 10 SY500H Excavator OMM Page Intentionally Blank ...

Page 30: ...2 8 SAFETY SY500H Excavator OMM Page Intentionally Blank ...

Page 70: ...3 40 MACHINE CONTROLS SY500H Excavator OMM Page Intentionally Blank ...

Page 172: ...5 64 MAINTENANCE SY500H Excavator OMM Page Intentionally Blank ...

Page 180: ...6 8 SPECIFICATIONS SY500H Excavator OMM Page Intentionally Blank ...

Page 194: ...I 8 SY500H Excavator OMM Page Intentionally Blank ...

Page 195: ...Page Intentionally Blank ...