19

Version: 20221219

B.

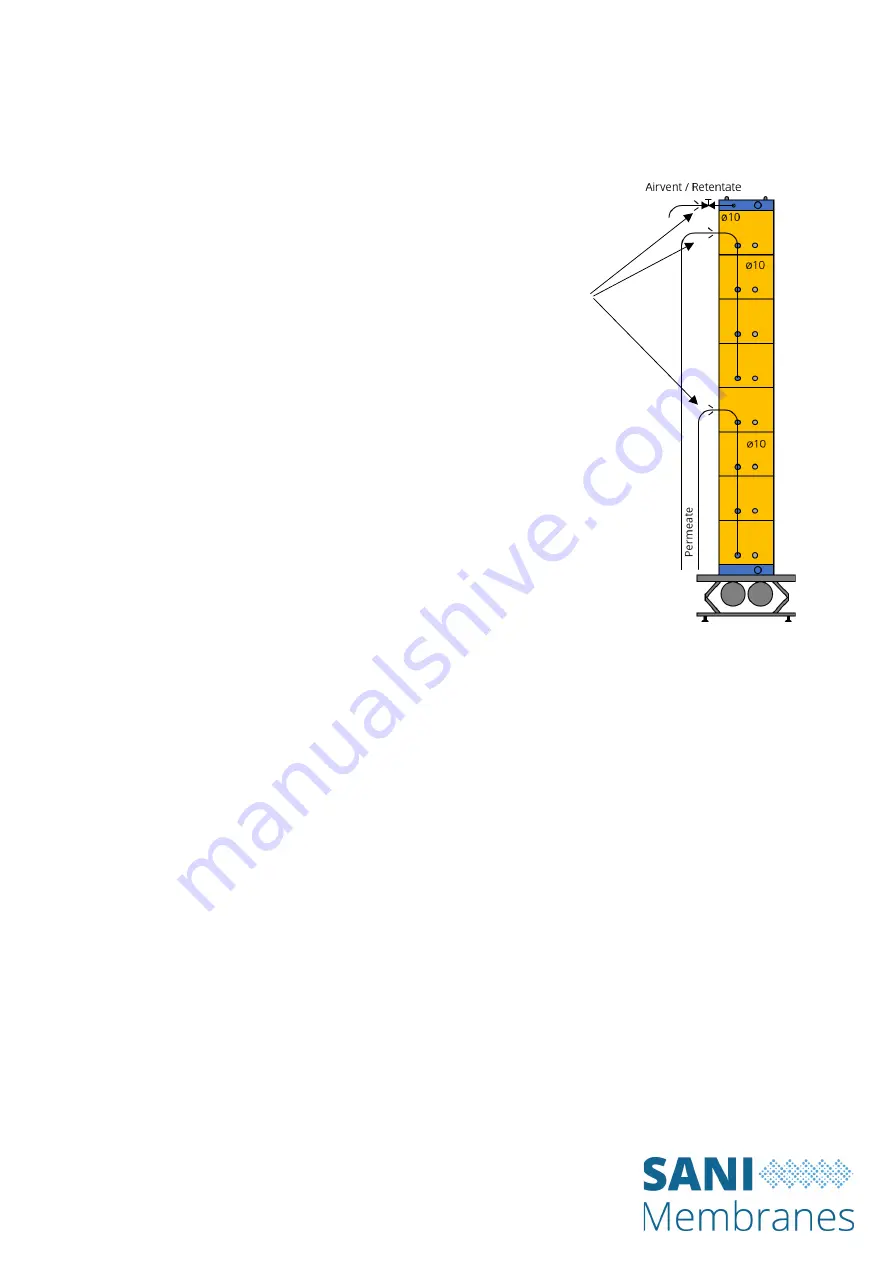

Permeate system

The manifold is designed to avoid negative

transmembrane pressure (TMP) as this can cause

damage to the membrane modules. A negative TMP can

occur when reducing the feed pressure dramatically or

stopping the feed system quickly.

In microfiltration applications it is often key to have a

low, uniform TMP. To facilitate this the manifold for

microfiltration systems leads the permeate up along the

modules, as shown in the illustration to the right. To

enable drainage of the permeate side a drain valve can

be included at the bottom of the permeate manifold.

The permeate rate may be controlled by using a positive

displacement type pump on the permeate line. This will

restrict the permeate flow and will enable unique process control at low uniform TMP during

microfiltration. Read more about this in Section E below (

“

Examples of membrane filtration

process configurations

”

).

For ultrafiltration applications the pressure conditions are less critical and the manifold can

instead be designed to lead the permeate down along the modules. A vent valve can

optionally be included at the top of the manifold to assist draining of the permeate side.

In general it is recommended to reduce the pressure drop in the permeate system by using a

larger diameter tubing between the Vibro-I and the collection tank.

Avoid

pressure

drop using

larger

diameter

tubing to

the

collection

tank