34

7. Installation Guides

7.1 Mechanical requirements and installation

Support structure

The support structure has to be provided and installed by the customer because they vary

from project to project. The following issues must be considered:

Weight tolerances:

Ensure that the support structure and the floor on which or the wall

against which the support structure has to be installed, is qualified to handle the complete

weight of the LED display screen.(which can be provided by manufacturer.

Environmental

conditions

: Humidity, wind, temperatures, rain, snow etc.

Location

: Outdoor/.Indoor, altitude, etc. Usually, for outdoor display screen, the customer

should build top cover and side cover for IP protection (Including waterproof and dustproof)

Ground stability

Front clearances:

For making sure there is sufficient free area in front of the LED display

screen and respect the maximum viewing angles and distance.

Local regulations regarding such installation

Tools for installation

Please prepare below tools before installation

Slot type screwdriver, Philips type screwdriver, spanner, Hexagonal bar, Hexagonal head

screwdriver, scissors, pincers, wire cutters, hammer, electric drill, electric welding,

Multi-meter, etc.

Summary of Contents for P10

Page 3: ...3 10 1 Cleaning 104 10 2 Calibration 105 10 3 Replacement steps 106 11 Appendix 119 ...

Page 12: ...12 3 2 Product Appearance ...

Page 13: ...13 ...

Page 14: ...14 3 3 Product design Decomposition chart ...

Page 15: ...15 Assembly drawing ...

Page 16: ...16 3 4 Product main components Module Power Supply Receiving Card Monitoring Card ...

Page 17: ...17 Fan Hub board Power data cables 16pcs DC power cables 8PCS and Flat cables 16 pcs ...

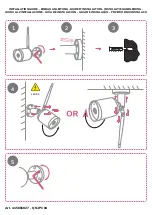

Page 35: ...35 Installation of cabinets Fixing of connect plate ...

Page 42: ...42 8 2 Port of Cabinet and serial number paint ...

Page 59: ...59 ...

Page 68: ...68 ...