30 _ Troubleshooting

No

Problem

What to do

4

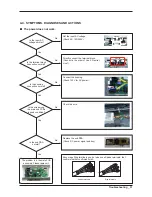

Blows fuses or trips circuit

breaker

- Is the belt connected well?

- Is the winding of the motor continuous? (Rotor winding, stator winding, generator)

- Is the motor protector normal?

• If above points are not found, the PCB assembly is out of order. Replace it.

5

Blows fuses or trips circuit

breaker (Gas Model)

• During ignition the dryer will draw 6 amps. With the burner ON, the dryer will draw 4.5 amps.

If the dryer is drawing amperages above this, then the house wiring, fuse box or circuit

breaker is suspected to be at fault.

• Igniter harness loose and shorted to base.

• Incorrect wiring or wire shorted to ground.

• Drive motor winding shorting to ground.

6

Will not heat (motor runs)

Open heating element.

• Hi-Limit trips easily or is open.

• Regulating thermostat trips easily or is open.

• Membrane switch open.

• Check Thermistor.

7

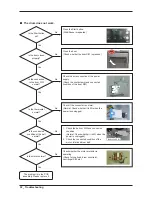

Will Not Dry Gas Model Poor

Gas Ignition

When the dryer is operated on a heat setting, the igniter should be energized and burner shall

fire within 45 seconds at 120 VAC. The failure of a component in this system will usually be

indicated by one of three symptoms (No.8, No.9, No.10)

8

The igniter does not glow

If the igniter does not heat up, remove power and using an ohmmeter, check the following:

• Open flame sensor

• Open igniter

• Shorted booster coil

• Open wiring

• Bad motor switch ( Neutral supply)

• No power from control ( L1 supply)

9

Igniter glows - No gas ignition

If the igniter heats up but the main burner flame is not ignited, remove power and using an

ohmmeter, check the following:

• Open secondary coil

• Open holding coil

• Open wire harness

• Stuck flame sensor (Stuck closed)

10

The gas is ignited but the

flame goes out

If a normal ignition takes place and after a short while the flame goes out, check for the

following:

• Radiant sensor contacts opening prematurely.

• Weak gas valve coil may open when stressed by higher Temps.

• Weak Hi-Limit

• Poor venting

• Bad drum seals

11

Improper drying clothes

wrinkled Rough texture long

dry time

• The lint filter is not clean.

• Any restriction in the exhaust.

• The outside exhaust hood damper door stuck closed.

• Is the exhaust too long, too many elbows, flex ductwork installed.

• Poor intake air available for the dryer.

• Incorrect tumbler speed. Tumbler belt slipping.

• Blower impeller bound; check for foreign material in blower area.

• Customer overloading dryer.

• Check clothing labels for fabric content and cycle selected.

• Clothes too wet due to insufficient spin out by washer.

12

Noisy and/Or Vibration

• “Thumping” Check for loose tumbler baffle, rear tumbler roller(s) worn or misaligned, out-of-

round tumbler or high weld seam on tumbler.

• “Ticking” Check for loose wire harness or object caught in blower wheel area.

• Scraping Check for front or rear bulkhead felt seal out of position or worn tumbler front

bearings.

• “Roaring” Check for blower wheel rubbing on blower housing or bad motor bearings.

• Popping or squealing sound. Check for a sticky or frayed belt.

Summary of Contents for DV448AEP

Page 28: ...26 _ Disassembly and Reassembly memo ...

Page 49: ...Exploded views and Parts list _ 47 memo ...

Page 63: ...Exploded views and Parts list _ 61 memo ...

Page 71: ...Exploded views and Parts list _ 69 memo ...

Page 85: ...Exploded views and Parts list _ 83 memo ...

Page 93: ...Exploded views and Parts list _ 91 memo ...