70

EB 8384-6S EN

Mounting and start-up

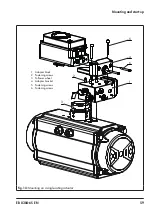

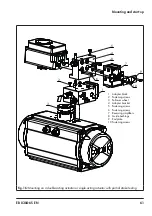

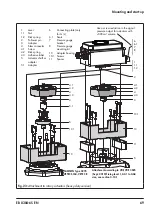

5.9

Reversing amplifier for

double-acting actuators

For the use with double-acting actuators, the

positioner must be fitted with a reversing am

-

plifier, e.g. the SAMSON Type 3710 Revers

-

ing Amplifier (see Mounting and Operating

Instructions

u

If a different reversing amplifier (item no.

1079-1118 or 1079-1119) is used, follow the

mounting instructions described in sec-

The following applies to all reversing am-

plifiers:

The signal pressure of the positioner is sup-

plied at the output 1 of the reversing amplifi

-

er. An opposing pressure, which equals the

required supply pressure (Z) when added to

the pressure at output 1, is applied at output

2.

The following relationship applies:

output 1 + output 2 = Supply pressure (Z).

Connect output 1 to the signal pressure con-

nection on the actuator that causes the valve

to open when the pressure rises.

Connect output 2 to the signal pressure con-

nection on the actuator that causes the valve

to close when the pressure rises.

Î

Set slide switch on positioner to AIR TO

OPEN.

How the outputs are marked depends on the

reversing amplifier used:

−

Type 3710:

Output 1/2 = Y

1

/Y

2

−

1079-1118 and 1079-1119:

Output 1/2 = A

1

/A

2

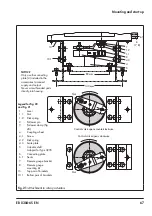

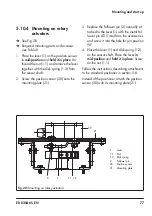

5.9.1

Reversing amplifier

(1079-1118 or 1079-

1119)

Î

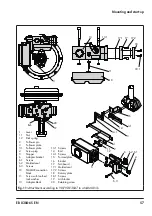

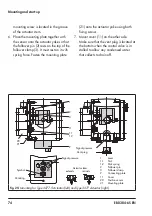

1. Mount the connecting plate (6) from the

accessories in Table 7 to the positioner.

Make sure that both O-rings (6.1) are

seated correctly.

2. Thread the special nuts (1.3) from the ac-

cessories of the reversing amplifier into

the boreholes of the connecting plate.

3. Insert the gasket (1.2) into the recess of

the reversing amplifier and slide both the

hollowed special screws (1.1) into the

connecting boreholes

A

1

and

Z

.

4.

Place the reversing amplifier onto the

connecting plate (6) and screw tight us-

ing both the special screws (1.1).

5.

Use a screwdriver (8 mm wide) to screw

the enclosed filters (1.6) into the connec

-

tion boreholes

A

1

and

Z

.

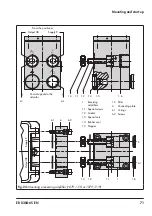

Air can escape uncontrolled from the signal

pressure connection.

Do not unscrew the sealing plug (1.5) out of

the reversing amplifier.

The rubber seal (1.4) is not required and can

be removed when the sealing plug is used.

6.

After initialization, set Code 16 (Pressure

limit) to No.

Note

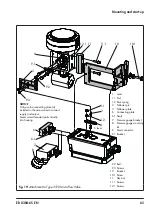

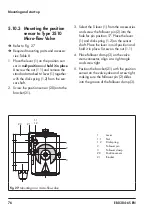

A

1

1.5

1.6

1.3

6.2

6

6.1

1.2

1.1

1

1.6

Z

A

2

1.4

A

1

A

2

Z

A

1

Output 38

Supply 9

Output 38

Supply

9

1.3

1.2

1.1

From the positioner

Control signals to the

actuator

1

Reversing

amplifiers

1.1 Special screws

1.2 Gasket

1.3 Special nuts

1.4

Rubber seal

1.5 Stopper

1.6 Filter

6

Connecting plate

6.1 O-rings

6.2 Screws

Fig. 24:

Mounting a reversing amplifier (1079-1118 or 1079-1119)

NOTICE

!

Note

Summary of Contents for TROVIS SAFE 3730-6

Page 12: ...12 EB 8384 6S EN...

Page 16: ...16 EB 8384 6S EN...

Page 22: ...22 EB 8384 6S EN...

Page 40: ...40 EB 8384 6S EN...

Page 42: ...42 EB 8384 6S EN...

Page 82: ...82 EB 8384 6S EN...

Page 90: ...90 EB 8384 6S EN...

Page 96: ...96 EB 8384 6S EN...

Page 132: ...132 EB 8384 6S EN...

Page 152: ...152 EB 8384 6S EN...

Page 155: ...EB 8384 6S EN 155...

Page 156: ...156 EB 8384 6S EN...

Page 157: ...EB 8384 6S EN 157...

Page 158: ...158 EB 8384 6S EN...

Page 159: ...EB 8384 6S EN 159...

Page 160: ...160 EB 8384 6S EN...

Page 161: ...EB 8384 6S EN 161...

Page 162: ...162 EB 8384 6S EN...

Page 163: ...EB 8384 6S EN 163...

Page 164: ...164 EB 8384 6S EN...

Page 165: ...EB 8384 6S EN 165...

Page 166: ...166 EB 8384 6S EN...

Page 167: ...EB 8384 6S EN 167...

Page 182: ...182 EB 8384 6S EN...

Page 183: ...EB 8384 6S EN 183...