EB 8355-2 EN

5-19

Installation

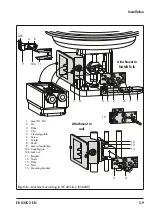

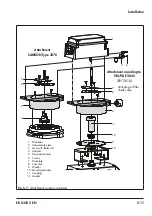

Actuator stem extends (FA): fail-close

(for globe and angle valves)

Required supply pressure =

Upper bench range value + 0.2 bar,

at least 1.4 bar.

Actuator stem retracts (FE): fail-open

(for globe and angle valves)

For tight-closing valves, the maximum signal

pressure pstmax is roughly estimated as fol-

lows:

pst

max

= F +

d² · π · ∆p

[bar]

4 · A

d

= Seat diameter [cm]

∆p

= Differential pressure across the valve

[bar]

A =

Actuator area [cm²]

F

= Upper bench range value of the

actuator [bar]

If there are no specifications, calculate as

follows:

Required supply pressure =

Upper bench range value + 1 bar

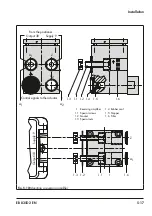

Pressure regulator

After tilting the cover plate back, the pres-

sure regulator (9) can be continuously ad-

justed. When the adjuster is turned counter-

clockwise as far as it will go, signal pres-

sures for spring ranges up to 2.5 bar are

controlled. When the adjuster is turned

clockwise all the way, signal pressures for

spring ranges up to 6.0 bar are controlled.

If the signal pressure must not exceed a cer-

tain value, this limit can be adjusted using a

pressure gauge (accessories).

5.5

Adjusting the positioner

Intrinsic safety rendered ineffective in in-

trinsically safe devices.

Î

Only connect intrinsically safe devices in-

tended for use in intrinsically safe circuits

to certified intrinsically safe input-con

-

nected units.

Î

Do not place intrinsically safe devices

back into operation that were connected

to intrinsically safe input-connected units

without certification.

Î

Do not exceed the maximum permissible

electric values specified in the EC type

examination certificates when intercon

-

necting intrinsically safe electrical equip-

ment (U

i

or U

0

, l

i

or I

0

, P

i

or P

0

, C

i

or C

0

and L

i

or L

0

).

Starting point and set point

When adjusting the positioner directly at the

control valve, the travel (opening angle) must

be adapted to the set point.

−

With a set point, for example 4 to

20 mA, the valve must move through its

entire travel range from 0 to 100 %

, top).

−

On mounting the positioner on rotary ac-

tuators, an opening angle, for example 0

to 70° must be assigned to the set point.

−

The starting point is based on the

CLOSED position of the valve. Depend-

ing on the control valve version ("actua-

tor stem extends" or "actuator stem re-

tracts") and the operating direction of the

WARNING

!

Summary of Contents for 3767

Page 10: ...1 6 EB 8355 2 EN...

Page 14: ...2 4 EB 8355 2 EN...

Page 58: ...6 2 EB 8355 2 EN...

Page 60: ...7 2 EB 8355 2 EN...

Page 70: ...10 2 EB 8355 2 EN...

Page 72: ...11 2 EB 8355 2 EN...

Page 74: ...12 2 EB 8355 2 EN...

Page 76: ...13 2 EB 8355 2 EN...

Page 78: ...14 2 EB 8355 2 EN...

Page 79: ...EB 8355 2 EN 14 3...

Page 80: ...14 4 EB 8355 2 EN...

Page 81: ...EB 8355 2 EN 14 5...

Page 88: ...14 12 EB 8355 2 EN...

Page 89: ...EB 8355 2 EN 14 13...

Page 90: ...14 14 EB 8355 2 EN...

Page 91: ...EB 8355 2 EN 14 15...

Page 92: ...14 16 EB 8355 2 EN...

Page 93: ...EB 8355 2 EN 14 17...

Page 94: ...14 18 EB 8355 2 EN...

Page 95: ...EB 8355 2 EN 14 19...

Page 96: ...14 20 EB 8355 2 EN...

Page 97: ...EB 8355 2 EN 14 21...

Page 98: ...14 22 EB 8355 2 EN...

Page 99: ...EB 8355 2 EN 14 23...

Page 100: ...14 24 EB 8355 2 EN...

Page 101: ...EB 8355 2 EN 14 25...

Page 102: ...14 26 EB 8355 2 EN...

Page 103: ...EB 8355 2 EN 14 27...

Page 104: ...14 28 EB 8355 2 EN...

Page 109: ......

Page 110: ...2 EB 8355 2 EN...

Page 111: ...EB 8355 2 EN 3...